www.industry-asia-pacific.com

23

'20

Written on Modified on

Paragraf: From Research to Commercial Graphene Electronics

Progressing from research to commercialisation in just five years, Paragraf has created a remarkably sensitive graphene-based magnetic sensor. Technical Director, Dr Ivor Guiney, reveals how.

In 2014, three years before the launch of Paragraf, Professor Sir Colin Humphreys wanted to make a device that combined GaN with graphene. He and I were working in his Cambridge Centre for Gallium Nitride at the University of Cambridge, and we had both heard about how graphene was going to have a huge impact on the world of electronics.

So, Colin called the UK's leading graphene centre to ask for a two-inch diameter piece of device-quality graphene to combine with our 2-inch GaN wafer. He was told that such graphene didn't yet exist. We couldn't believe it. Despite the wonder material's much publicised potential, such a small piece of decent-quality graphene wasn't even available.

In 2015, Colin recruited Simon Thomas into our research group to work on the growth of GaN electronic device structures. Simon is experienced in thin film growth, having worked in the semiconductor industry for many years. With Simon’s expertise, we also developed the growth of large-area graphene, using existing equipment available to us. We only had a small amount of money for growth gases, etc., from one of Colin's EPSRC grants that encouraged speculative research, but within a couple of years we had developed a new way to grow up to 8-inch diameter device-quality graphene.

Our modified, direct deposition method was scalable, used industry-standard equipment and, crucially, didn't rely on the usual metal catalysts and transfer techniques that introduce contaminants. Perhaps most notably, this was also at a time when organisations worldwide had spent millions of pounds trying to do the same thing.

But developing robust graphene growth was just the beginning. From the start, we had all wanted to make not only graphene but also graphene-based devices. Simon and I had backgrounds in semiconductor materials, and with our new growth process we started to synthesise rudimentary devices.

Results came quickly. Colin's group is renowned for GaN device development, and by early 2017, we had fabricated graphene-GaN LED heterostructures, showing for the first time that a graphene fabrication process could be integrated into GaN LED production. We decided to focus on graphene-based, magnetic Hall-Effect sensors next.

Market opportunities

The reason we targeted Hall sensors is that they are simpler devices to process than GaN LEDs, which made sense when proving novel devices in a short timeframe. Also, and only recently, a multinational engineering and technology company had created a graphene-based Hall-Effect sensor, said to be up to 100 times more sensitive than the silicon equivalent, using tiny flakes of exfoliated graphene and assembling the sensor by hand. However, that same company had also publicly announced that commercialisation could be up to a decade away due to the lack of growth methods for large-scale graphene.

Our scalable, contamination-free deposition method not only solved this problem, but we had already fabricated technically mature devices.

Throughout graphene deposition and device development, Colin, Simon, and myself had amassed a wealth of solid intellectual property, and we felt the time was right to take our technology to market. So, with this powerful message, we approached potential investors.

Initially, investors were highly sceptical. Many had already invested in graphene companies that had gone nowhere and investors had lost a lot of money. However, Colin’s track record of successfully spinning out GaN LED companies encouraged a major investor known to him to support us, and other investors then followed rapidly.

In 2017, the three founders launched Paragraf, with Simon taking on the role of Chief Executive, Colin as Chairman and myself as Technical Director. By October 2017, Paragraf had closed a £2.9 million seed round, and in May 2019, it had raised £12.8 million in our Series A round and come Christmas 2019, this figure had swollen to £16.2 million.

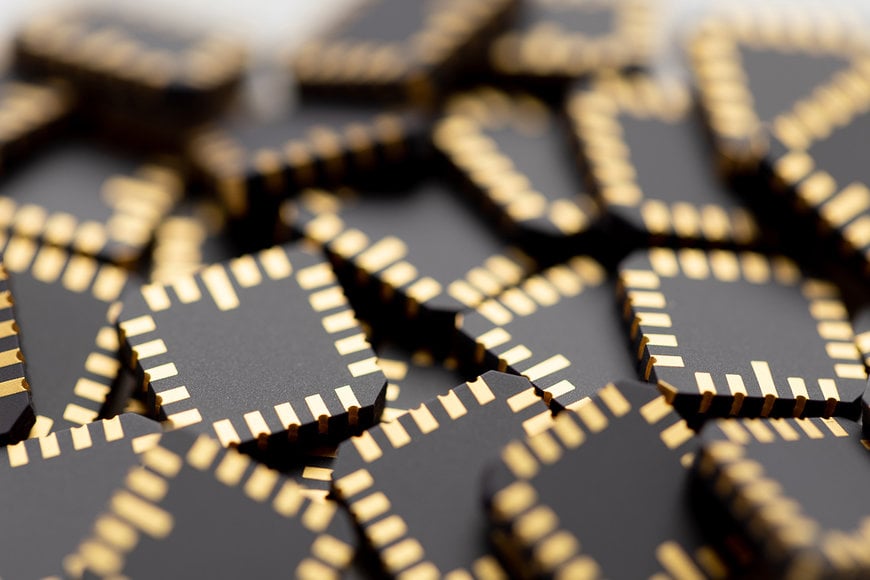

With our investor funds, Paragraf has moved into premises in Somersham, near Cambridge, to drive large-scale development of mass-market, graphene-based devices, and excitingly, our first major product, the graphene Hall-Effect sensor, has recently been launched.

Thanks to everyone's hard work, the GHS Series of graphene Hall-Effect sensors are ready to map magnetic fields with high precision in an extraordinary range of applications. From scientific research and healthcare to aerospace, industrial and automotive industries, the magnetic sensors will deliver unrivalled sensitivity and range.

Looking back, we have swiftly commercialised graphene for electronic devices when many in industry doubted this could be done.

Looking to the future, Paragraf plans to deliver a range of world-leading graphene-based electronics devices and sensors to benefit society and the UK economy.

www.paragraf.com