www.industry-asia-pacific.com

06

'20

Written on Modified on

DUNKERMOTOREN INCREASE FLEXIBILITY OF PRODUCTION IN THE AUTOMOTIVE SECTOR

The extreme dynamics of the automotive industry requires a high degree of flexibility from the car manufacturers.

Smart production plants and flexible logistics systems are necessary to meet the constantly increasing global competition. These systems must be adapted quickly and flexibly in order to economically meet the increasing demand for diversity.

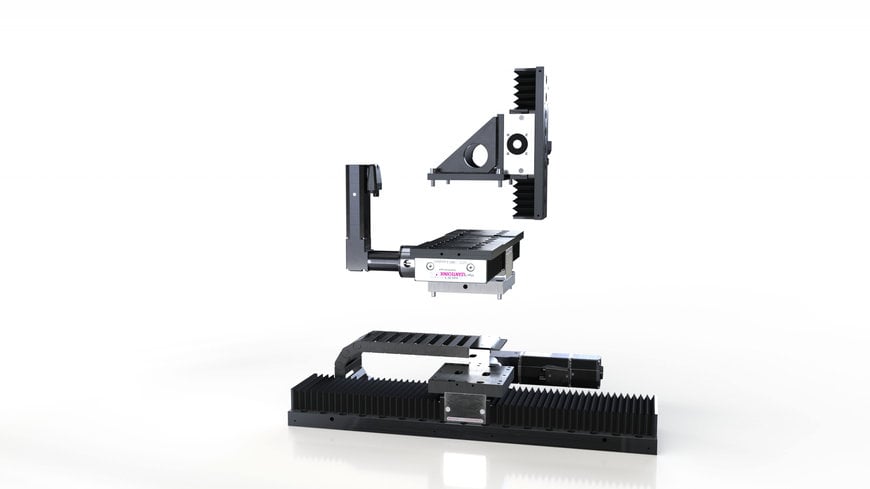

Such flexible solutions are offered by the company Leantechnik from Oberhausen, which is strongly represented in automation technology, including the automotive sector. The system was developed for a well-known automobile manufacturer with the aim of optimizing the body shell. The new development of the company Leantechnik offers the possibility to economically produce a multitude of product variants within one line. By means of the so-called NC locators, the positions of holders, clamps or centring can be individually adjusted and product components can be flexibly accommodated. The system consists of AFP axes in longitudinal, lifting and/ or transverse axes. These axes each include a 24 VDC servo motors with integrated freely programmable control and CANopen interface. This means that many different car models can be produced on a single production line without having to convert the production line. Leantechnik designed the NC locators as a modular system for this purpose and assembled them from individual axes, drives and fasteners. This allows them to be moved in any direction in relation to each other, which means that the system can be flexibly adapted to the production conditions.

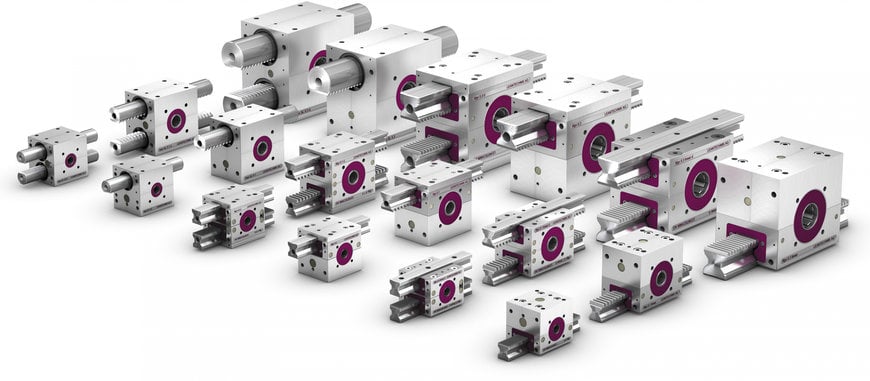

The central component of this system is the motor solution from Dunkermotoren. The axis system is implemented with two motor variants. One of the two variants consist of a brushless DC motor BG 45 with integrated electronics and CANopen interface, an E 38 brake and two planetary gear variants, an in-line and an angular gear variant. The second drive variant consists of a BG 65S brushless DC motor with integrated electronics and CANopen interface, an E 90 brake and two available planetary gearhead variants.

The stronger motor solution is mainly used for vertical positioning of the body or for larger bodies in order to apply greater force to the axles.

The motors of Dunkermotoren are used in the axle unit for travel in XYZ direction. Up to 24 such axle units are used per transport unit ("table") for a body-in-white, in order to be able to move the car manufacturer's body-in-white flexibly on the table. The structure of the axle system (flexibly movable in XYZ direction) enables the car manufacturers to carry out welding or gluing work on the floor assemblies, for example, on different body models on only one table. It is therefore no longer necessary to change the table for each model. This gives the manufacturer the flexibility to adapt production much more quickly to individual customer requirements, which above all increases productivity and cost-effectiveness.

Dunkermotoren is considered the world market leader for brushless DC motors with integrated electronics. The company offers various motor variants up to 3.9 kW output power. The modular system enables flexible, customer-specific drive design from 1 piece.

www.dunkermotoren.com