www.industry-asia-pacific.com

28

'20

Written on Modified on

HEXAGON LAUNCHES HIGH QUALITY CHUCKS AS PART OF THE PORTFOLIO OF PART HOLDING ACCESSORIES FOR CMMS AND OTHER MEASUREMENT DEVICES

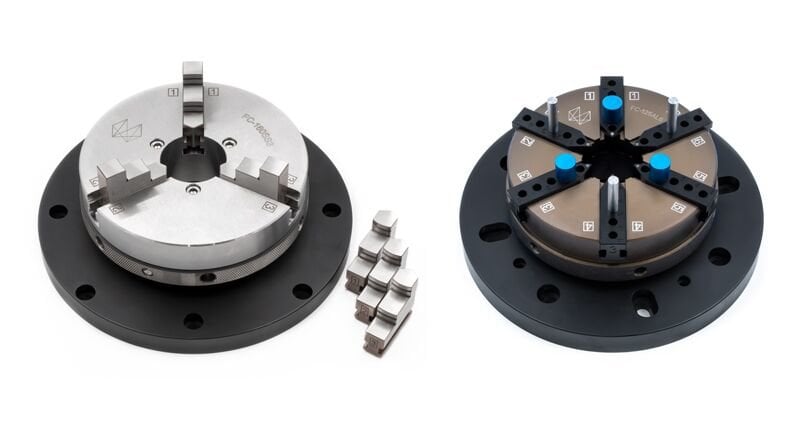

Hexagon’s Manufacturing Intelligence division has launched new high-quality chucks to enhance the measurement of cylindrical and rotationally symmetrical parts, one of the most common tasks undertaken on coordinate measuring machines (CMMs).

Hexagon’s Swift-Fix Chucks are designed to hold pieces in place with the help of either three or six jaws to ensure the best possible accessibility to the part. The highly accurate, self-centring and repeatable Swift-fix Chucks deploy consistent forces on all jaws and help users achieve the highest levels of precision and quality in the measurement process. A large and easy-to-handle adjustment range mean parts with various diameters can be mounted quickly. Depending on the application, parts can be held on the inner or outer diameter.

All three-jaw chucks contain jaws for inner and outer clamping to ensure the best possible positioning across a full range of applications. Six-jaw chucks are equipped with different position and stop pins, so that the clamping can be flexibly adjusted to changing applications.

Swift-Fix Chucks are manufactured from stainless steel or aluminium with additional ALTEF® coating, making them completely resistant to corrosion, wear and scratches. In addition, all clamping jaws are vacuum hardened and polished. Hexagon’s choice of materials and attention to quality mean all chucks are easy to maintain and retain their high levels of precision and repeatability during long term use.

Thanks to flexible mounting plates, Swift-Fix chucks can be mounted directly on the machine table. Additionally, all available chucks are compatible with Hexagon Swift-Fix baseplates and Leitz rotary tables.

www.hexagonmi.com