www.industry-asia-pacific.com

25

'20

Written on Modified on

Yamaha Motor Launches Support Software for RCX3 Series Robot Controller

New Functions Significantly Reduce Robot System Setup Time

Yamaha Motor Europe announced today that it will launch the RCX-Studio 2020 support software for the RCX3 Series of robot controllers on May 14, 2020. This new product adds new functions such as a 3D simulator and program templates (automatic sample generation) to the existing RCX-Studio Pro software, and also features usability enhancements.

RCX-Studio 2020 enables on-screen equipment layout work, teaching, program creation, debugging, etc. even if robots are not connected. By doing so, this software makes a significant contribution to accelerating robot system setup and further reducing operator workload.

RCX-Studio 2020 Main Features

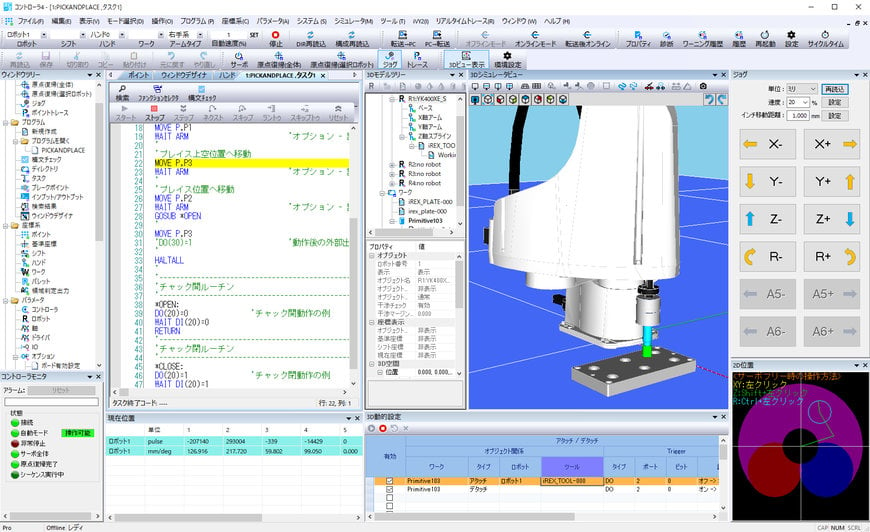

1) 3D simulator function

Shows the robots and peripheral devices in 3D, simulating robot operation on your computer. The simulation feature allows users to work on robot layout, teaching, debugging, etc. even if robots are not connected, checking on-screen for interference between robots and peripheral devices in advance of equipment startup. Prior evaluation of layout enables prevention of interference with customers’ production equipment.

- 3D CAD incorporation: Compatible with STL, Wavefront OBJ, VRML2.0, and STEP*

- Jog movement and teaching

- Expression of peripheral devices and workpieces with simple shapes (primitive)

- Teaching using 3D CAD data characteristics*

- Robot trajectory display

- Robot and peripheral device interference checking (also handles situations where workpieces are moved manually)

- Handles multiple robots (up to four) *Pro version only. Compatible formats: AP203, AP214

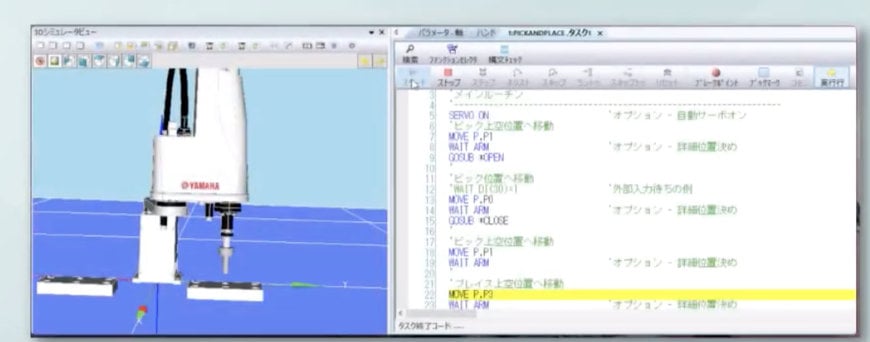

2) Program template function (automatic sample generation)

RCX-Studio 2020 includes program templates for ten popular applications. Program templates can be automatically generated simply by following the operation order steps. Not requiring command input makes program creation easier, enabling significant reductions in program creation time.

Compatible Applications:

- Pick and place

- Palletising

- Coating

- Switching execution programs

- Conveyor tracking- Coating

- Switching execution programs

- Pallet picking using AI vision

- Coating using AI vision

- Correcting pickup deviations using AI vision

- Correcting pickup deviations using AI vision and correcting placement position

- Correcting pickup deviations using AI vision and correcting placement position (without master)

3) Custom window creation function

GUIs for operators such as those shown on control panels can be created easily. Focusing on only the functions necessary for operations means that problems such as data deletion and overwriting due to mistaken operation can be prevented, and also enables creation of operation screens tailored to customers’ particular equipment.

4) Other existing functions

RCX-Studio 2020 inherits the rich functionality of the previous RCX-Studio Pro, supporting the operation of Yamaha robots from setup to maintenance.

- Emulator function

Checks the operation time by using the same data as actual machines.

- Real-time tracing function

Robot status parameters such as the load factor of each axle and positioning checking can be monitored in real time.

- Cycle time calculation function.

The operation cycle time between two points can be calculated quickly.

- Data comparison function

The difference between two specified data sets can be displayed visually. Direct comparison with online data is also possible, enabling significant reductions in maintenance time.

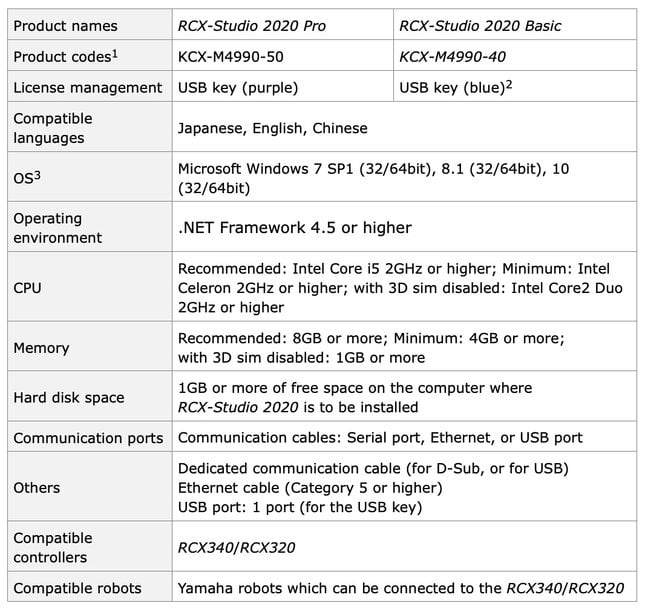

Specifications

1: Software package product codes. Both of the software products can be downloaded from our website.

2: Common with the previous RCX-Studio Pro.

3: Windows 7, Windows 8.1, and Windows 10 are trademarks or registered trademarks of Microsoft Corporation in the United States and other countries. Other company or product names listed are trademarks or registered trademarks of the respective companies.

www.yamaha-motor.eu