www.industry-asia-pacific.com

22

'20

Written on Modified on

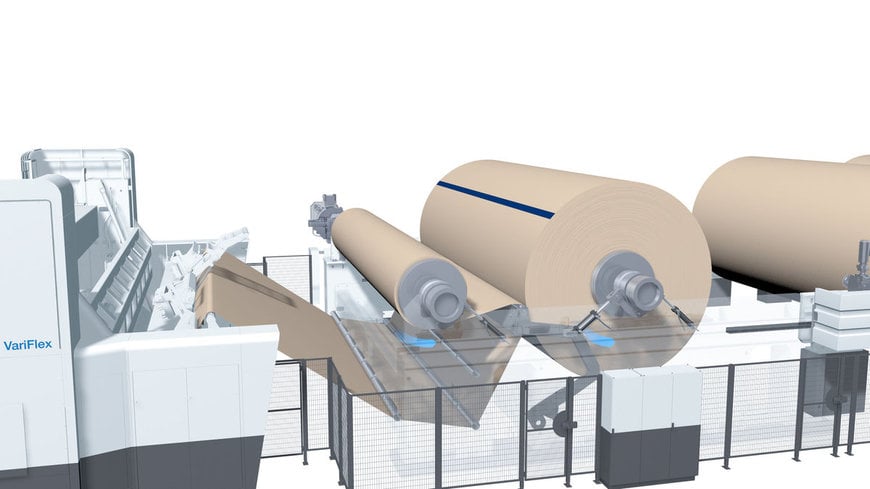

Voith’s new double unwind TwinDrive significantly boosts winding capacity

With the new TwinDrive double unwind, paper manufacturers achieve an increase in winding capacity of up to 20 percent.

Voith strengthens its winder product portfolio with the introduction of the new TwinDrive double unwind, another solution for significantly boosting winding capacity. The system was specifically developed for paper manufacturers that impose the most stringent efficiency requirements on their production process. Following the successful developments of the VariFlex Performance winder, with a set change time of less than 25 seconds, and SmoothRun, the active drum damping system to minimize vibrations, TwinDrive complements these solutions ideally to meet the highest capacity and customer requirements.

Increased capacity and maximum production rates

The new TwinDrive double unwind ensures a winding capacity that is up to 20 percent higher compared to the use of conventional unwinding systems. This advantage is achieved through the additional unwind position and fully automated jumbo roll changes. With conventional systems, the winding capacity is limited due to downtimes during jumbo roll changes. The fully-automated process of TwinDrive eliminates these downtimes, resulting in a significant increase in both efficiency and productivity.

Depending on customer requirements, the paper web is connected automatically with a FlyingSplice or ButtSplice system. The significant time savings result in higher production rates. Depending on production conditions, considerably more jumbo rolls can be processed by the winder.

"The new TwinDrive double unwind enables us to make yet another important contribution to achieving an even more efficient and sustainable paper manufacturing process," says Matthias Wohlfahrt, Product Manager at Voith Paper, who has driven the development of the new double unwind.

"This innovative system allows our partners and customers to benefit from high production capacities that make an important contribution to the overall efficiency of the plant. This applies to new facilities and also, in particular, to rebuilds if the existing winder is being operated at the limits of its capacity and has previously prevented an increase in production."

~ Matthias Wohlfahrt, Product Manager at Voith Paper

Fast assembly and short installation times

The new TwinDrive double unwind features short assembly and installation times. The system is fully tested before delivery and shipped in three large units. This results in short assembly times on site and a fast start-up curve, which is important for new paper machines as well as for upgrading existing systems. With its robust and stable design, TwinDrive ensures the best winding quality and highest availability in high-performance applications.

Simplified operation and reduced number of manual operator interventions

For ease of operation and maximum safety, the control concept is intuitive and operator-friendly. The jumbo roll change is done automatically, resulting in no need for manual operator intervention during roll change. This facilitates operation, increases work safety and reduces manual interventions at the winder to a minimum.

www.voith.com