www.industry-asia-pacific.com

11

'20

Written on Modified on

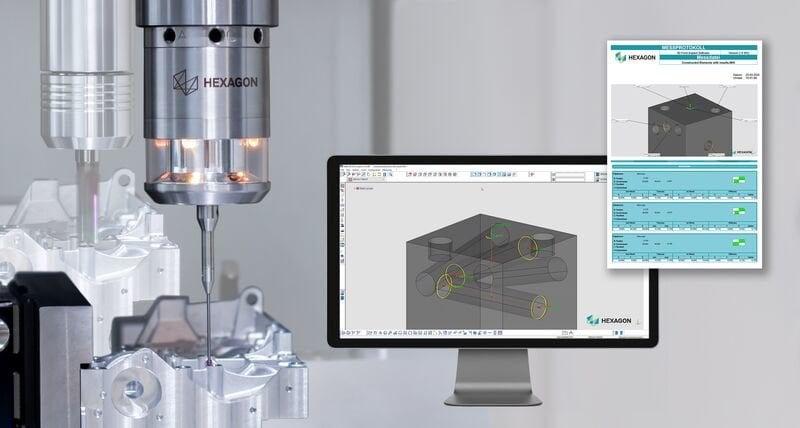

New version of Hexagon’s 3D Form Inspect for machine tools with enhanced tolerance and reporting functions

The new 3D Form Inspect version 2.8 SR2 for machine tools allows users to deploy measurement data for statistical evaluations in Q-DAS, includes new extended reporting functions and enhances the setting of standard and individual tolerances.

Uniquely flexible, functional and easy-to-use, 3D Form Inspect from Hexagon’s Manufacturing Intelligence division is a market-leading software for machine tool measurement. It allows manufacturers to quickly measure and record ruled geometries and forms on all sides of a part with all axes of a machine tool. Popular features include Best-Fit for automatically aligning parts on machines, as well as patented calibration strategies. And Hexagon’s investment in developing new capabilities ensures manufacturers can rely on 3D Form Inspect to help them adapt to changing market requirements.

Extended tolerance functions

The latest enhancements to 3D Form Inspect help manufacturers meet the growing demand for machined parts that attain the ISO2768 standard for production tolerances. With 3D Form Inspect users can inspect for ISO2768 tolerances with a single click, including individual tolerances for single measurement points, and publish results in the measurement report.

New reporting functions

Users of 3D Form Inspect value its clear measurement reports and the ability to adjust its design and data formats. In the latest version, deviation bars can be included for each value, clearly showing if the measured point is within tolerance.

Some production environments require parts to be measured both on the machine tool and on a coordinate measuring machine. 3D Form Inspect now makes it simple to compare measurement reports from machine tools and from CMMs that use PC-DMIS software, by displaying results from both software systems in a similar format.

Design of elements out of measurement objects

Many users need to determine elements, dimensions or distances that cannot be directly measured.

3D Form Inspect enables them to do so by generating lines or axes between two measurement objects, such as a bore or a cylinder, and determining the distances or angles. This is especially important when producing gears and powertrains, where the distances between axes are an extremely relevant indication of quality.

Q-DAS exports for statistical evaluation of measurement results

Measurement results are an important source of information about how to improve mid- and long-term production quality. 3D Form Inspect now enables manufacturers to undertake in-depth analysis by exporting machine tool measurement data for further processing by Q-DAS Statistical software.

Available on OPS eroding machines

In line with growing demand, 3D Form Inspect can now be installed on eroding machines from the manufacturer OPS. The software is compatible with Andronik 360 and System 1 controls.

The new 2.8 SR2 version of 3D Form Inspect is available immediately. Existing holders of a 3D Form Inspect software maintenance agreement will receive the update and training without additional fees.

www.hexagonmi.com