www.industry-asia-pacific.com

04

'20

Written on Modified on

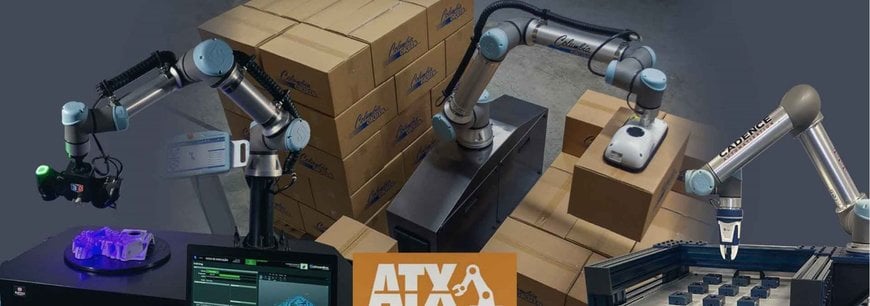

Universal Robots Showcases New Cobot Powered Solutions for Palletizing, Metrology and Machine Tending at ATX West

Attendees at the largest automation technology trade show in the Western U.S. will experience how collaborative robots from industry leader Universal Robots now automate some of the most sought-after tasks in a manufacturing industry facing severe labor shortages.

When manufacturers can't staff tasks on their production lines it severely affects the bottom line resulting in drastic increases in overtime, cycle time and downtime. With the U.S. unemployment rate remaining at 3.5 percent, the lowest in 50 years, 10,000 baby boomers retiring every day and few millennials interested in joining the manufacturing industry, companies are increasingly looking at automation to solve production challenges. At ATX West in Anaheim, CA, Feb 11-13, the pioneer and market leader of collaborative robots, Universal Robots (UR), will show attendees how cobots now power ergonomically unfavorable, repetitive and even technically complex tasks that manufacturers can’t staff.

Fast and Cost-Efficient Palletizing with miniPAL

UR’s ATX booth 4815 is the launch pad for OEM partner Columbia/Okura’s new miniPAL™, a mobile palletizer product powered by the UR10e cobot arm. The flexible miniPAL™ with a footprint of 11’x13’ can palletize at two pallet locations for optimized operation. The latest design showcased at ATX includes two safety mats and two area scanners that detect when people enter the work envelope, allowing the system to meet even higher speeds when not in collaborative mode. The system plugs into 110V AC wall power, can be set up in less than a day, and delivers an average payback between 8-10 months, depending on application and industry.

PARTS INSPECTION IN AUGMENTED REALITY

Many manufacturers are still using hand tools like calipers, micrometers, or height gages for parts measurement, causing problems with consistency and measurement for complex geometries. 3D scanning provides a more comprehensive inspection report for in-process and final verification for a wide variety of industries. To automate this process, 3D Infotech has developed the UMA Smart Station, a standardized system integrated with Universal Robots collaborative robots. Driven by 3D Infotech’s Streamline software, the UMA station allows for the adding of 3D scanners to the end of UR3e, UR5e and UR10e cobot arms for advanced Scan-to-CAD comparison and inspection capabilities, including GD&T (geometric dimensioning and tolerancing).

A recent UMA station customer, Royal Technologies, needed to scan a wide range of parts. “Some operators would miss certain features of the part, resulting in bad parts, now we catch anything that is deviated. To summarize, it has improved speed, quality, and overall performance,” says Trevor Lipsey, launch coordinator at Royal Technologies.

At the show, 3D Infotech will also mount a projector on the cobot arm, projecting inspection results back onto the part through the company’s Spotlight AR++ software, an augmented reality solution that can project colors maps, inspection results, and visual instructions directly on the part. Following the automated 3D scanning and inspection of the part, visitors will be able to visually see the results on the physical object rather than viewing a 2D inspection report. Spotlight AR++ further expands the collaboration between man and machine as the cobot can provide the operator with visual instructions from many points of view.

www.universal-robots.com