www.industry-asia-pacific.com

19

'19

Written on Modified on

NORD at PIPOC in Kuala Lumpur

From 19th to 21st of November 2019, NORD DRIVESYSTEMS will be exhibiting at the PIPOC International Palm Oil Congress and Exhibition at the Kuala Lumpur Convention centre in Malaysia. The focus will be on drive solutions for the chemical, food and vegetable oil industry.

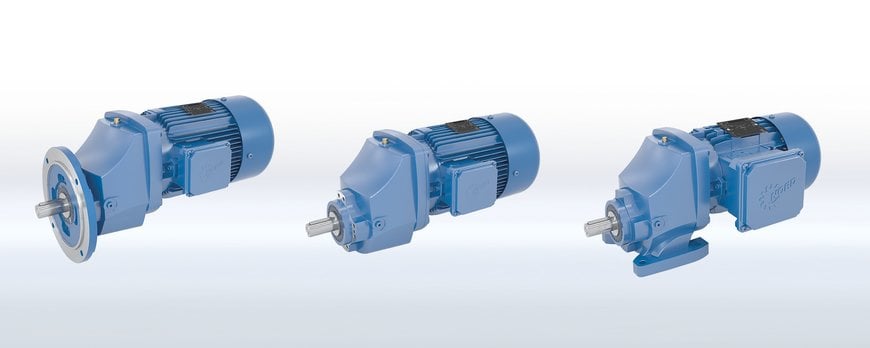

As one of the world's leading complete suppliers of electrical, mechanical and electronic drive technology, NORD DRIVESYSTEMS provides solution and system expertise for more than 100 industries. At the PIPOC NORD will be presenting its wide range of gear units for the chemical, food and vegetable oil industry. NORD DRIVESYSTEMS has extended its range of single stage NORDBLOC.1 helical gear units with three larger sizes. These drive units provide high output torques as well as maximum radial and axial load capacity, high efficiency and long life. The successful series has recently been extended upwards with three sizes and now offers a power range from 0.12 to 45 kW. The drive units cover the torque range up to 1,000 Nm and, thanks to optimised bearings, can reliably handle large axial and radial forces. They are characterised by high efficiencies, compact design and top reliability. The modular design provides wide application flexibility due to numerous configuration and mounting options.

Compact design meets ultimate reliability

The innovative NORDBLOC.1 helical gear units impress with their compact design and ultimate reliability. They do not have any separating joints or closing caps. This increases the stability of the product and at the same time provides a smoother surface on which neither liquids nor solid materials can accumulate. The FEM-optimised UNICASE housing ensures maximum strength and rigidity. The modular design provides wide application flexibility due to numerous configuration and mounting options. All variants are available as flange mounted (B5 or B14), or foot/flange mounted versions. Options for IEC and NEMA motor mounting as well as a wide range of equipment variants for shafts, bearings and lubrication can be flexibly implemented.

Cooling concept for high power limits

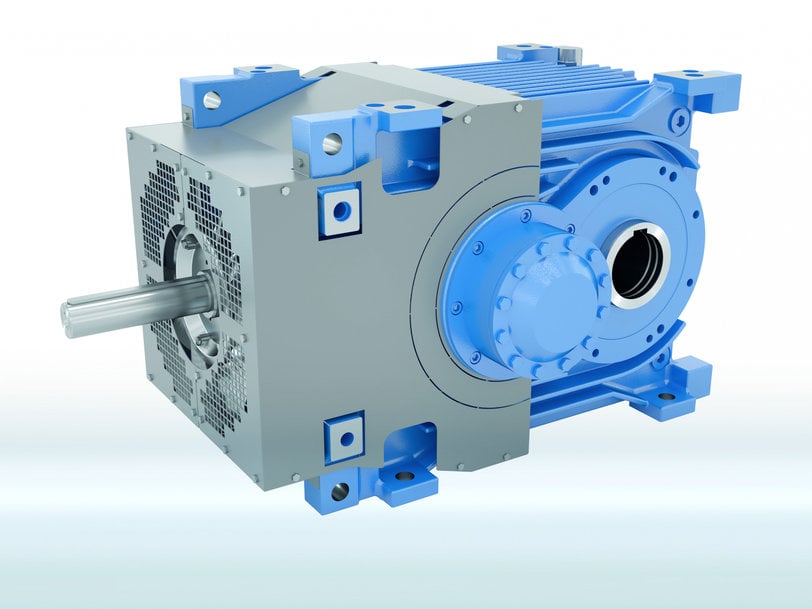

The NORD range has included MAXXDRIVE industrial gear units for ten years and in this time, they have been developed further. The latest generation supplements the long-standing series with an application-optimised two-stage angled gear unit, which is especially suitable for conveyor belt systems and can be individually tailored to the particular application. The power and speed range was specially designed for the industry, in which low speed ranges are required in combination with high powers.

Output torques of the MAXXDRIVE® XT series range between 15 and 75 kNm with speed ratios of 6.3 to 22.4. MAXXDRIVE® XT industrial gear units are available in seven sizes for powers from 50 to 1,500 kW. In contrast to the previous designs, as standard the series is equipped with a heavily ripped UNICASE housing with an integrated axial fan. Due to the increased surface and the air guide covers, the cooling air flow is optimised and a very high thermal limiting power is achieved. In many cases, addition cooling is not required. Large roller bearings and centre distances increase the load capacity and service life of the components.

The latest generation of MAXXDRIVE® XT industrial gear units is specially designed for applications which require low speed ratios in combination with high powers