Milacron to Present Latest, Cutting-Edge Technologies at K 2019

Milacron Holdings Corp. (NYSE: MCRN) (“Milacron”), a leading industrial technology company serving the plastics processing industry, is pleased to announce their upcoming participation at K 2019.

K Show will take place from October 16-23rd in Dusseldorf, Germany. Milacron will be displaying its industry-leading technologies including Milacron injection molding machines, Mold-Masters hot runners, control systems and co-injection, DME mold technology solutions, and industrial supplies in Hall 1 Booth C05.

More products, machines, and services will be highlighted in additional future press releases over the coming 4 weeks as we approach the show with enthusiasm. This is just a glimpse of what will be in store.

The industry’s only integrated plastics processing provider, Milacron, has combined the individual strengths of industry-leading product brands Ferromatik, Mold-Masters, DME, TIRAD, and CIMCOOL. Technologies such as injection, co-injection, extrusion, hot runner systems, control systems, and mold technologies have been unified to create the industry’s most comprehensive integrated plastics solutions provider.

Milacron will have an assorted display of innovative products and solutions at K 2019 from our industry-leading brands. Milacron will focus on automotive, medical, packaging, and technical applications.

Here’s a sample of what visitors can expect:

Q-Series

Milacron’s new Q-Series product line provides the latest servo-hydraulic technology in a toggle injection molding envelope. The Q-Series design is inspired by the durable MTs series and the proficiency that was provided by the F-Series. When combined, the globally offered Q-series will provide critical power when it is needed and use less power when it is not. The Q-Series can be built to suit ten tonnage offerings.

The US 55 to 610 (500-5.500KN) ton machines support multiple injection frames, providing an extremely wide range of flexibility with each clamp tonnage. These combinations provide a wider range of molding opportunities. The Q-Series is a true culmination of high efficiency, consistency, and globally engineered technology. The Q-Series is part of Milacron’s Quick delivery lineup, allowing the machines to be built and delivered to a manufacturing facility quickly.

Little time is required from a customer’s order to the start of production. Q-Series has been designed to fit the high expectations of toggle performance while providing extraordinary value. Leveraging the use of a servo motor in combination with hydraulic components, Q-Series provides exceptional repeatability and energy savings.

The clamp kinematics provide enhanced velocities while delivering a smooth and accurate operation. The clamp design provides for better tonnage linearity allowing minimum tonnage to go lower than previous toggle designs. The eco-friendly design generates savings in electrical power consumption, cooling requirements, and lower maintenance cost.

Elektron

Discover the versatility and value of the latest addition to our industry-leading all-electric product line. Building on decades of all-electric injection molding innovation, the Elektron from Milacron provides clean, precise, efficient production in a full range of applications.

It uses 60% less energy and 90% less water than hydraulic injection molding machines, reducing operating costs substantially. The engineered parallel movements paired with the servo-driven axes make the Elektron ideal for the reliable production of high-precision parts with fast repeatable movements.

This series features a completely new, FEA-optimized clamp design with a greaseless part drop area and absolutely no hydraulic oil, making it ideal for cleanroom operations. A robust 5-point toggle system optimizes operation utilizing large mold opening strokes in a compact design. The Elektron is designed for a full range of applications, in a wide variety of sizes, and offers outstanding value to customers to help them achieve their plastics manufacturing goals.

MPs

The new Maxima Performance Series builds upon the highly successful Maxima platform. The Maxima Performance Series addresses the market demand for higher performance, precision, and flexibility. This enhanced platform delivers faster cycle times, wider platens, a precision greaseless clamp guided on linear bearings, and integrated auxiliary capability.

Maxima Servo is one of Milacron’s most energy-efficient machines. The servo-hydraulic machine provides up to 70% energy savings over similar machines, with a reduction in molding costs, maintenance costs, and heat load on the factory floor.

The high-value injection molding machine combines the advantage of a precise and accurate 2-platen mechanism with advanced, user-friendly controls. This platform delivers the next level of performance for two-platen designs while maintaining Milacron’s center tonnage build technology.

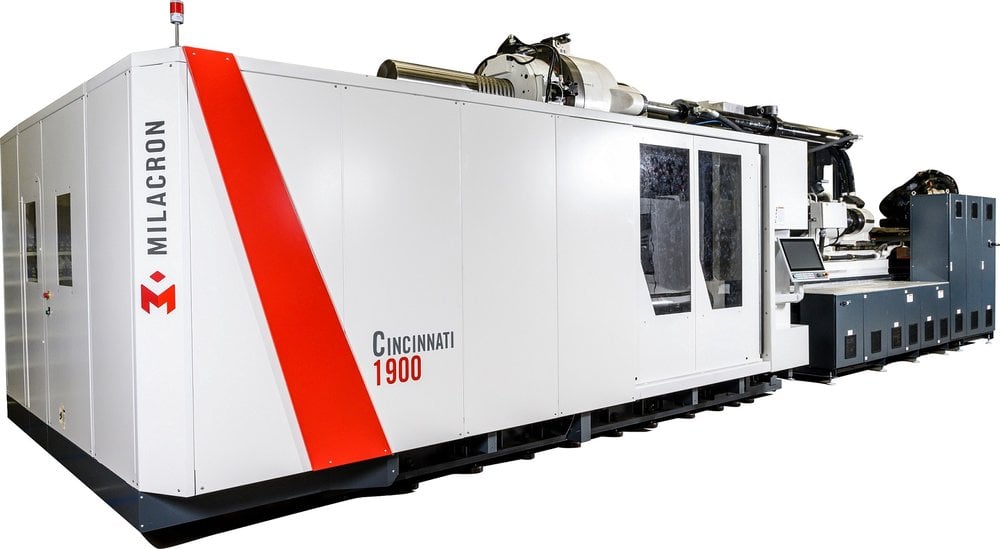

Cincinnati – CE

Milacron has excelled at manufacturing large tonnage injection molding machines for decades and is the global leader in the manufacture of these specialized machines. The Cincinnati is no exception. Proudly taking its name from Milacron’s home city of Cincinnati, The Cincinnati machine pays homage to all the Milacron employees past and present that have built Milacron into what it is today – the leader in plastics solutions, leading the way to what’s next in plastics.

The Cincinnati is a NEW large tonnage, true two-platen machine designed to meet the demands of the global automotive, appliance, and other large part molding markets. The Cincinnati product line expands on our industry-leading large machine technology with a platform that adds performance and a shorter footprint.

The Cincinnati’s enhanced machine specifications and performance are powered by proven Fanuc servo motor power packs for improved reliability, higher max mold weights, faster clamp speeds, and added tonnage sizes. The improved machine layout and enhanced access to the eject and die areas make operation, maintenance, and servicing easier.

M-Powered

M-Powered adds sophisticated data analytics through various applications to bridge the gap between the assets and plant monitoring, as well as taking MES-like functionality to the next level. M-Powered provides a competitive advantage by increasing machine efficiency, reducing unplanned downtime, and improving quality.

Leveraging the latest in Industrial Internet of Things (IoT) and data science, M-Powered provides unique insights and intelligence into your machine’s operations. Stay ahead of maintenance and production issues with predictive analytics. Connect your assets to any existing infrastructure using our suite of APIs. Receive updates and alerts any time through our intuitive dashboards, over any browser, or by e-mail or even text messages to your cellular telephone.

M-Powered connects parts, service, rebuilds & retrofits with our preventative maintenance service to provide a unified, strong service and aftermarket offering through our ServTek aftermarket brand: delivering greater operational efficiencies.

The M-Powered connect portal puts key intelligence at your fingertips – in real-time, anywhere – be it in the office, through your (smart)phone, or tablet computer. Milacron continues to invest in the entire M-Powered suite delivered by our ServTek aftermarket brand, taking customer performance to new levels.

iMFLUX

The M-Powered iMFLUX Module is the cutting-edge technology of adaptive processing control. Backed by years of processing exploration, the M-Powered iMFLUX Module will help to improve part quality, but also decrease the energy required to produce it. As part of the M-Powered suite of tools, the iMFLUX Module and molding technology will allow for several real-time adjustments to mold and material changes.

These real-time adjustments coupled with the other M-Powered analytical tools are designed to assist in improving OEE through adaptive process control. iMFLUX combines advanced data collection with intentional solutions so that your assets are as effective as possible and further assisting your team in maximizing productivity. Using iMFLUX, molders can increase productivity by up to 50% on existing injection molding machines.

The process is ideal for most molding applications, but is especially advantageous for wide specification materials, recycled materials, and can help a biomaterial work for many more applications. This will continue to be an increasing sustainability focus for molders and brand owners.

Extrusion – Twins, Screws & Barrels

Milacron excels in offering customized and tailored screws and barrels for complex extrusion systems. Milacron’s aftermarket service offers counter-rotating twin screws as well as single screws that provide solutions to improve productivity and efficiency.

To extend the life of any customer investment, each screw and barrel features a proprietary tungsten wear coating developed specifically for longevity in the extrusion process. Milacron extrusion solutions involve advanced manufacturing technologies that lead to improved product quality, reduced delivery lead time, and improved customer field service support.

Milacron’s new product offerings include counter-rotating twin extruders, single screw extruders, and die heads. Additionally, Milacron can provide gearbox rebuilding and retrofit packages to accommodate counter-rotating twin and single screw extruders, barrels for counter-rotating twins and single screw extruders, refurbishing Milacron and competitive brand extruders.

ServTek

Milacron ServTek works to bring you the industry’s most extensive line-up of services and tools to help you get the most from your plastics processing machinery. From price matched parts, machinery service, and consultation, to rebuilding/repurposing of older plastics machinery, Milacron ServTek provides you with the widest range of tools and resources required to improve your processes and your bottom line.

As your business needs change, your machines need to change with you. Whether you need retrofitting of your current machines to adjust to different outputs or a complete rebuild of older machines that still have life in them, Milacron can service your injection, extrusion, blow molding, and auxiliary machines.

Milacron’s Technical Service Team works with you to review your new requirements, evaluate processes, and offer upgrading and rebuilding ideas to keep your machines running. We improve your machine efficiency, increase productivity, and uptime to help you achieve your output goals.

Milacron also offers training on the upgraded equipment for your company as well as our parts and services program to keep your machines working at peak performance.

Mold-Masters

Mold-Masters SeVG+, our most advanced actuation control system, is now available for ALL applications. SeVG+ is a servo-driven system that provides absolute control and precision over individual valve pin opening and closing actuation profiles. Fully adjust pin position, acceleration, velocity, stroke, timing, and sequence. Critical capabilities for demanding applications that greatly enhance molded part quality including large automotive parts that require Class “A” surface finish.

Each SeVG+ system includes an SeVG+ controller, which features a large, easy-to-use touch screen display, on-the-fly adjustments, compact cabinet dimensions, and available TempMaster hot runner temperature control integration.

SeVG+ valve gate control is available on Mold-Masters:

- Fusion-Series G2

- Dura+

- Master-Series

- Summit-Series Hot runner systems

DME XPress™ – Any Shape, Any Steel program

DME introduces enhancement to its XPress™ mold base range, by adding 25 additional steel grades, all European certified through its “Any Shape, Any Steel” program. Through this enhancement, customers benefit from the widest Industry Market offerings and flexibility for their Mold bases within a 24/48/72-hour shipment service throughout Europe, combined with the essential mold components.

Furthermore, in the frame of the program, DME has expanded the range of its mold components to offer new varieties of standard leader pins, bushings, graphite guiding pins, insulating plates, and centering rings. On top, DME announces it has been registered with major designer software programs such as Topsolid, Siemens NX, and DS Catia to facilitate mold design for its customers. 3D & CAD data is available 24/7 as well through our eSTORE and possible to download in multiple formats.

DME CoolingCare – Reduced cycle time/Improved mold productivity

DME CoolingCare is the new automatic device for cleaning, diagnostics, and maintenance of mold cooling channels. Cooling is a key factor impacting cycle time improvement for the majority of the molder community, mold designers, and mold makers. With DME all-in-one CoolingCare maintenance solutions, customers can benefit from easy manipulation, non-supervised run, water-temperature controllers, and heat exchangers.

It provides the first ever Industry 4.0 capability with built-in modem for online diagnostics and service, a dedicated application for mobile devices allowing for the online monitoring of the cleaning process, report database, and automatic adjustment system. DME offers expert advice and innovative technology of CoolingCare with various financing solutions.

www.milacron.com