www.industry-asia-pacific.com

03

'19

Written on Modified on

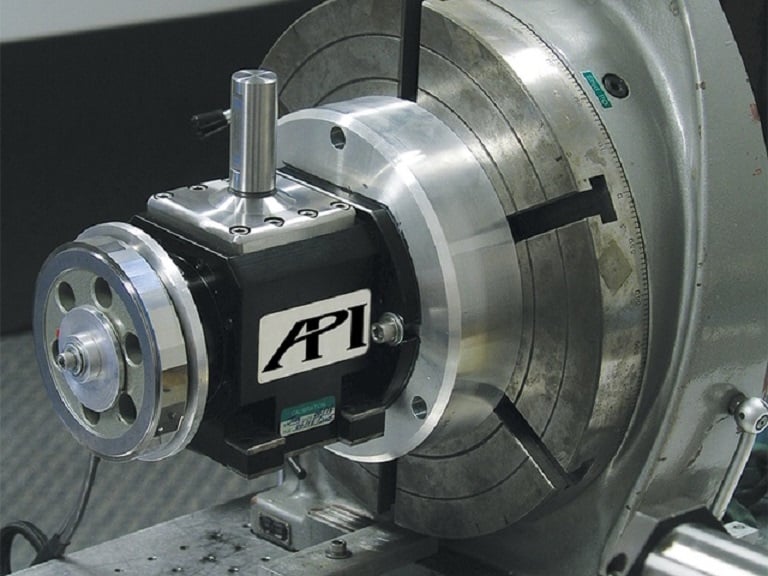

API Swivelcheck measures Rotary Machine Axis Errors

Swivelcheck measures and calibrates machine-tool rotary axes, tilt tables and pendulum axes.

SWIVELCHECK can operate in automated or manual modes and includes API’s Intellicomp™ software for control, data acquisition and reporting, SWIVELCHECK can also be used in conjunction with the API XD laser interferometer to measure horizontal rotary table position. SWIVELCHECK can be mounted off-centre of the rotating axis to measure the swivel axis of trunnions without need for disassembly of critical machine tool components.

SWIVELCHECK is easy to set-up offers +/- 400 degree swing and allows tilting axes to be checked at the spindle nose offering true accuracy to be reported over systems that check at the motor and do not detect ‘lost motion’. The Intellicomp software provides a direct import of measured axis data to machine-tool CNC controllers allowing an update of system parameters for improved precision.

SWIVELCHECK provides an invaluable tool to validate machine tool rotary axis performance in general machine shops and users of sophisticated 5 axis machine-tools. As an alternative API services offers contract machine-tool calibration services throughout North America using SWIVELCHECK.

www.api.com