www.industry-asia-pacific.com

28

'19

Written on Modified on

RENGAGE™ and SupaTouch machine tool probing technologies: minimise cycle time, maximise productivity

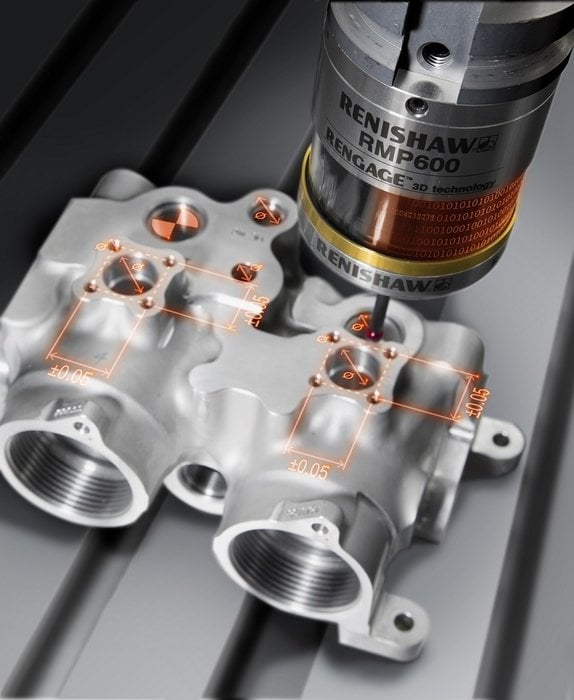

Global engineering technologies company, Renishaw, will demonstrate its RMP400 machine tool probe in combination with its SupaTouch technology at EMO Hannover 2019 in Germany, from 16th - 21st September.

The RMP400 joins the RMP600, OMP400, OMP600 and MP250 as part of Renishaw's range of machine tool probes with RENGAGE™ technology. They combine proven silicon strain gauge technology with ultra-compact electronics to deliver unbeatable 3D performance and sub-micron repeatability.

Excelling in the measurement of complex shapes and contours, RENGAGE probes are ideally suited to mould and die and aerospace applications, where the use of 5-axis machines are common. An ultra-low trigger force helps to eliminate surface and form damage on components – ideal for inspecting delicate workpieces.

Optimise probing cycles automatically

SupaTouch technology intelligently determines the fastest feedrates a machine tool can achieve whilst ensuring repeatable measurement. Its smart in-cycle decision making technology implements the quickest probing strategy (either one-touch or two-touch) for each measurement.

Smart decision making continues during component measurement – if a probe is triggered during machine acceleration or deceleration phases (which may happen due to variation in the positioning of the workpiece), then the measurement result will be inaccurate. After detecting these inaccurate measurements, SupaTouch technology automatically commands the probe to remeasure the surface at a more appropriate speed to ensure accuracy is maintained and no machine alarms are raised.

Minimise cycle time and maximise productivity

SupaTouch technology eliminates the need for manual optimisation of on-machine positioning feedrates, measurement feedrates and strategies. When compared with traditional software cycles, it provides a significant measurement time reduction of up to 60% on CNC machine tools.

The many proven benefits of Renishaw's established Inspection Plus software are enhanced with SupaTouch technology. With the software, users can significantly improve cycle times and on-machine measurement results, maximising the productivity and profitability of their machine tools.

www.renishaw.com