www.industry-asia-pacific.com

27

'19

Written on Modified on

Hexagon Continues to Cut Compressor Blade Measurement Cycle Time for Aero Engine Manufacturers

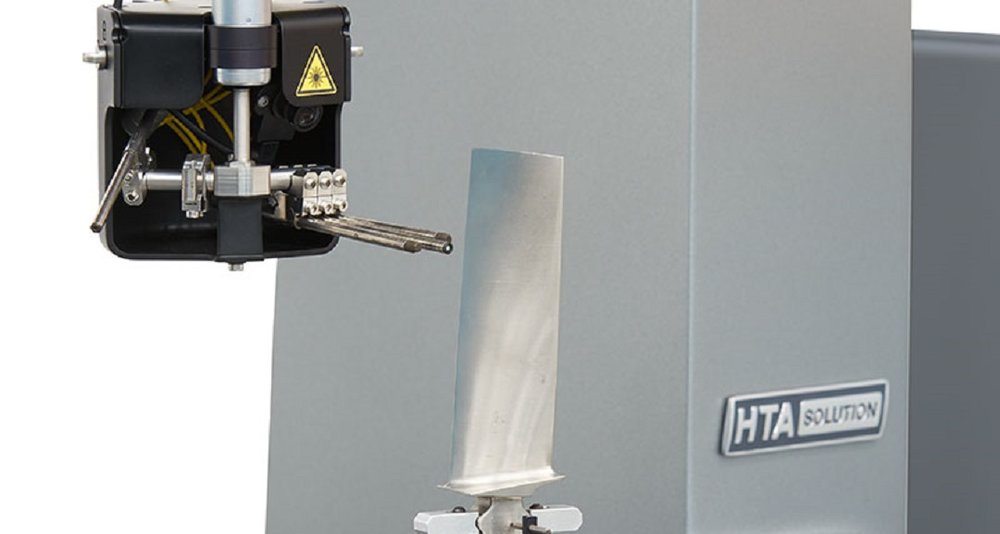

GLOBAL S HTA Optical Scanning System Further Streamlines the Creation and Execution of Measurement Routines.

It builds on the performance strength of the GLOBAL S HTA’s predecessor, which delivered a cycle time that was between two and five times faster than traditional tactile measurement.

New software upgrades now mean the GLOBAL S HTA further reduces measurement cycle time by up to 30% on average. Software improvements include easy, three-step aerofoil measurement routine creation and eliminating processing wait times during measurement execution for faster measurement cycle times.

The GLOBAL S HTA solution delivers high-density measurement data for enhanced aerofoil geometry analysis by using Hexagon’s HP-O non-contact scanning technology.

Its advanced HP-O Multi optical scanning probe technology deploys frequency-modulated laser interferometry technology to provide rapid non-contact scanning with sub-micron repeatability to verify the most challenging blade characteristics including knife edge, leading and trailing edges (LE/TE), 3D aerofoil geometries, platform, root and shroud features.

“Aero engine manufacturers face growing pressure to increase throughput while maintaining high levels of measurement accuracy,” says Ken Frescoln, Business Development Manager, Aero Engine, North America.

“With new and improved enhancements, GLOBAL S HTA is the only dedicated compressor blade solution on the market to offer such a significant reduction in measurement cycle time, providing a new level of throughput to meet customer demand. Another bonus is its intuitive user interface, designed to help quality engineers quickly access and analyse the data they need to improve processes and operate more efficiently.”

www.hexagonmi.com