www.industry-asia-pacific.com

03

'18

Written on Modified on

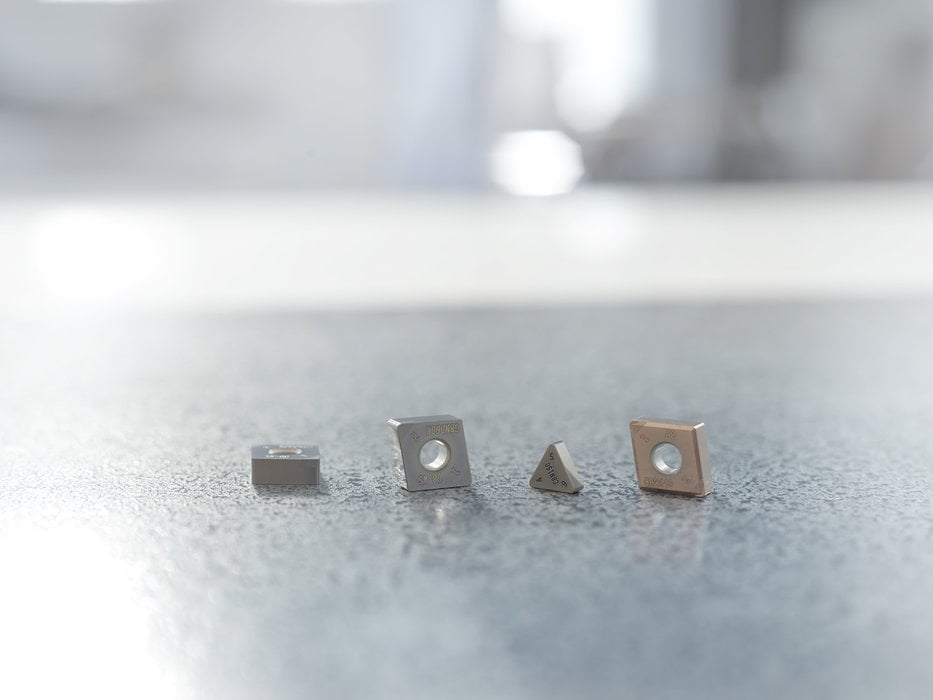

Seco Further Expands Extensive Line of PCBN Inserts

Seco Tools added a new grade format and several new geometries to its already expansive line of PCBN (polycrystalline cubic boron nitride) inserts. These additions enhance hard turning operations, broaden the extremely tough Seco CH3515 insert grade and introduce a new solid CBN150 insert grade, special long and short wiper geometries and laser-etched chipbreakers.

The Seco CH3515 insert grade offers high reliability in harsh cutting conditions with heavy interrupted cuts. The complete standard line now includes a broader range of sizes and geometries to optimize all hard-turning operations.

The CBN150 solid insert grade yields high surface-finish quality during light interrupted and continuous cuts in hard-turning operations. An increased number of cutting edges per insert reduces cost per edge.

New long WL and short WS wiper radii boost hard-turning feed rates and/or surface finish quality. The WL wiper inserts enable feed-rate increases of up to 100 percent while maintaining surface finish quality. With the WS wiper, cutting forces drop by as much as 15 percent for improved machining in low-stability conditions.

Seco’s new laser etched chipbreakers make the inserts extremely well suited for applications that transition from hard to soft part surfaces while allowing for increased depths of cut and feed rates over existing designs. The laser-generated flowing-radii chipbreakers exceed the performance of ground chipbreakers in generating smooth insert walls and reducing sharp corners. These improvements produce smoother chip flow and help prevent chipping, increasing chipbreaker application range.

For more information on the PCBN inserts, please contact a local Seco representative or visit our PCBN inserts product page.