www.industry-asia-pacific.com

14

'18

Written on Modified on

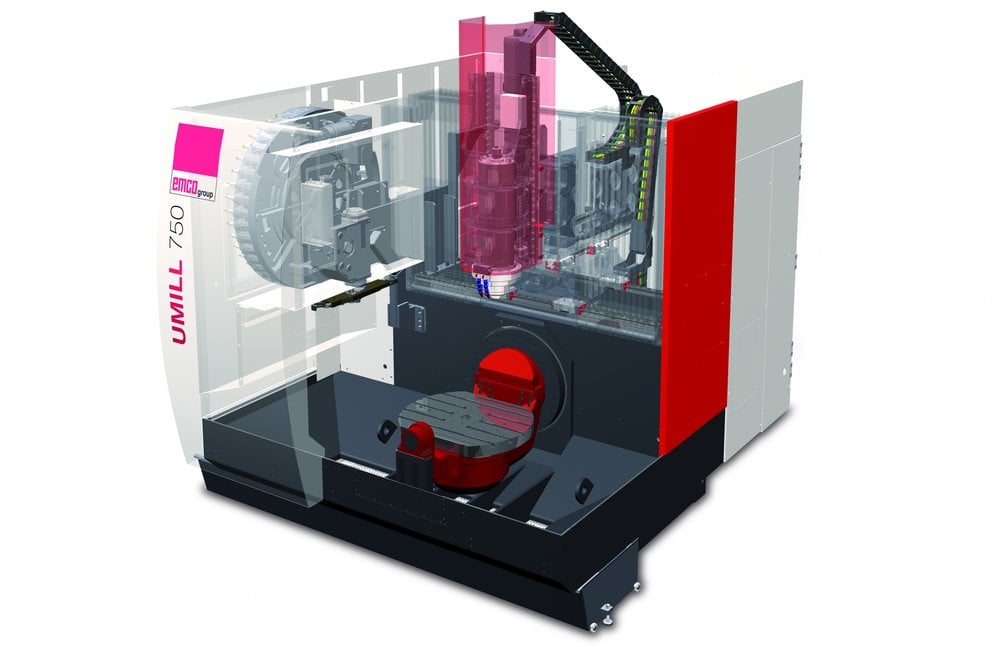

UMILL 750: Simultaneous 5-axis machining at the highest level

As a logical consequence of successfully establishing the Umill 1800 and Umill 1500 on the market, EMCO is now enlarging its portfolio with the new Umill 750 - size X = 750 mm. The efficient vertical milling machine for simultaneous 5-axis machining with its compact design and low installation space requirements allows even large components to be machined. The use of European components guarantees users highest precision and surface quality.

HALLEIN – TAXACH. EMCO with the combined milling expertise of its Italian subsidiaries has established the UMILL series. A further step towards the completion of the 5-axis milling machine product range is the compact UMILL 750 5-axis vertical milling machine which allows highly precise simultaneous 5-axis machining in only one clamping operation through the use of the latest control technology and smart structure solutions. And you get all of this at an excellent price-performance ratio.

The machine structure is constructed with an optimal combination of cast iron and welded steel thereby ensuring maximum stability and thermal symmetry. Supported by 45 mm roller guideways on the X- and Y-axis as well as a direct drive motor on the Z-axis, large travels of 750 mm in X, 610 mm in Y and 500 mm in Z make it possible to manufacture milling parts with maximum dimensions of 530 x 530 x 417 mm in the widest variety of lot sizes. Another positive feature is the high rigidity which produces optimal precision and excellent surface qualities on the workpiece. All axes have direct measuring systems for achieving perfect results. Thanks to the front support, already provided as standard for the table, workpieces with a weight of up to 400 kg can be machined without a loss in performance.

The basic configuration of the new UMILL 750 has a water-cooled motor spindle with a maximum speed of 15,000 rpm.

Despite the generous travels, the machine design is compact and ergonomic. Complex machining processes can be performed simply and efficiently with this 40x tool magazine. In addition, the user has the option to customise the tool magazine for 60 tool stations, with additional magazine sizes on request.

Tool holders complying with HSK-A63 are available for this motor spindle version. The large machine door makes it easy to load the machine. An automatic door for integrating intelligent automation systems can be optionally attached on the right-hand side. The work area is amply dimensioned. The machine can optionally be equipped with a slat band or scraper-type chip conveyor, or chip flushing system that provides efficient chip disposal. Thanks to simple and free access to various areas, the required maintenance can be carried out efficiently in a userfriendly way.

The UMILL 750 is optionally available with the latest control technology from Siemens (840D sl) or Heidenhain (TNC640). The controls are fitted to an ergonomically arranged control panel which is tilted forwards at an angle and equipped with a pivotal function. This solution creates optimal working conditions for the operator.

Digital process assistant for machine and process control

emcoNNECT stands for connectivity and networking in the production environment. It is a digital process assistant for the complete integration of customer and system-specific applications in the world of machine and process control. Users and their requirements are the central focus of each operating step: this allows operating procedures to be structured more efficiently while conserving the familiar, highly reliable performance of the machines in all operating modes.

The hardware basis for emcoNNECT is formed by a 22" industrial touch control panel and an industrial PC (IPC). Thanks to easy and quick updating and configuration, emcoNNECT is perfectly prepared for future requirements.

The range of available apps is continuously being expanded. As of now, for example, you may download our Shopfloor Data app as an option for the collection of machine and operating data. It ensures comprehensive monitoring of all machines as well as process organisation in the production area. This product is characterised especially by machine and manufacture independence and mobile access to the machine state using a smartphone or tablet PC.

In order to minimise machine downtimes, we are currently developing an app for targeted preventive maintenance – Guardian. We will be happy to show you a first version of this application at our booth at the AMB.

emcoNNECT is a standard feature of all machines equipped with Siemens 840D sl control. Upon completion of the ongoing developments for HEIDENHAIN 640 and FANUC 31i, emcoNNECT will be available on all control platforms.

The EMCO commitment of "Made in the heart of Europe" of course also applies to the UMILL 750. The machines are completely developed and produced in central Europe in cooperation with European brand manufacturers that meet the highest standards in terms of quality, productivity and efficiency.

The UMILL 750 is the ideal vertical milling centre for simultaneous 5-axis machining of complex workpieces in small or large quantities with high requirements for precision and surface finish. The machine is particularly suitable for tool construction & mould making, contract manufacturer, industrial companies, such as automotive suppliers, general mechanical manufacturing and advanced training institutions.

Technical data:

Travels and tolerances

Travel X-axis [mm] 750

Travel Y-axis [mm] 610

Travel Z-axis [mm] 500

Swivel range B-axis +/- 100°

Turning range C-axis n x 360°

Motion speed X/Y/Z [m/min] 50

Table

Length x width [mm] 750 x 600

Max. workpiece weight [kg] 400

Main spindle (motor spindle)

Speed [rpm] 50 - 15000

Spindle power [kW] 20

Torque [Nm] 100

Tool magazine

Number of tool stations 40 (60)

Tool changing time (tool to tool) [sec]* 5,4

Max. tool diameter [mm] 80

Max. tool length [mm] 250

Max. tool weight [kg] 8

*According to VDI 2852

Table dimensions 750 x 600 mm,

for workpieces with a weight of up to 400 kg

Test machining of a sphere in brass

5-axis simultaneous machining of a turbine blade in aluminium