www.industry-asia-pacific.com

22

'26

Written on Modified on

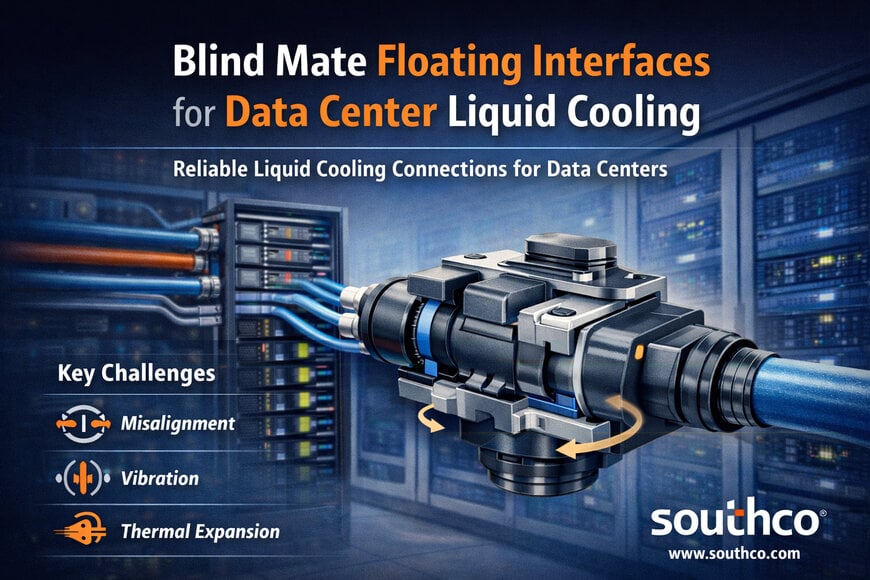

Blind Mate Floating Interfaces for Data Center Liquid Cooling

Southco introduces a high-tolerance floating connection mechanism designed to improve reliability and energy efficiency in liquid-cooled data center infrastructure.

www.southco.com

As liquid cooling moves into mainstream use for high-density computing, mechanical tolerances at coolant interfaces are emerging as a limiting factor for efficiency and uptime. Southco has released a blind mate floating mechanism intended to address alignment, vibration, and thermal expansion challenges in modern data center cooling systems.

Why interface tolerances matter in liquid-cooled data centers

Rising chip power densities in AI, HPC, and hyperscale environments are pushing air cooling toward physical limits, accelerating adoption of liquid cooling at rack and server level. While liquid cooling offers substantially higher heat transfer efficiency, its performance depends on stable, low-resistance fluid connections.

Guidelines from the Open Compute Project indicate that a 1 mm mechanical misalignment at a liquid cooling interface can increase flow resistance by approximately 15%, raising pump energy consumption by around 7%. In large installations with thousands of interfaces, these losses directly affect power usage effectiveness (PUE) and operating costs.

In practice, deviations arise from several sources: cumulative rack installation tolerances in mixed EIA-310-D and Open Rack V3 deployments, vibration during transport and operation, and thermal expansion of metal manifolds under temperature swings of 50 °C or more. Conventional rigid connectors, typically limited to ±0.5 mm static tolerance, are not designed to accommodate these combined effects.

Blind mate floating mechanism: technical approach

Southco’s blind mate floating mechanism is designed to decouple sealing performance from precise mechanical alignment. The system allows connection without direct visual alignment, supporting automated deployment and service operations in dense rack environments.

The floating structure provides multi-axis compensation, absorbing radial misalignment and axial displacement caused by installation variation, vibration, and thermal expansion. A self-centering feature returns the interface to a neutral position when disconnected, preserving available tolerance for repeated mating cycles and supporting compatibility with Open Rack V3 requirements.

Sealing performance is qualified against ASME B31.3 pressure criteria, including burst pressure testing at 300 psig, targeting long-term operation in continuous duty data center environments. The design is intended for use in cold-plate and rack-level manifold architectures where repeated connect–disconnect cycles are expected during server replacement or upgrades.

Operational implications for digital infrastructure

By reducing flow resistance penalties associated with misalignment, floating blind mate interfaces can lower pump energy demand and contribute to improved PUE in liquid-cooled facilities. Tool-less blind connection also shortens maintenance windows, enabling faster server swaps and reducing downtime risk in 24/7 operations.

The mechanism supports modular expansion and mixed-vendor environments aligned with open hardware standards, an increasingly important requirement as data centers scale AI and accelerated computing capacity.

Position in the evolving cooling ecosystem

Industry roadmaps for Open Rack V3 architectures project liquid cooling penetration exceeding 40% in hyperscale data centers. Within this context, floating blind mate interfaces address a specific but critical layer of the cooling stack: the mechanical reliability of fluid connections under real-world tolerances.

Southco indicates ongoing development in materials, including high-performance thermoplastics, and future integration of sensing capabilities for flow and temperature monitoring, aligning mechanical interface design with broader digital supply chain and infrastructure observability requirements.

Conclusion

As liquid cooling becomes a structural element of next-generation data centers, connection interfaces are shifting from passive components to performance-critical systems. Blind mate floating mechanisms represent a response to measurable efficiency losses and reliability risks observed in large-scale deployments, providing a mechanical foundation for stable, energy-efficient operation in high-density computing environments.

www.southco.com

Why interface tolerances matter in liquid-cooled data centers

Rising chip power densities in AI, HPC, and hyperscale environments are pushing air cooling toward physical limits, accelerating adoption of liquid cooling at rack and server level. While liquid cooling offers substantially higher heat transfer efficiency, its performance depends on stable, low-resistance fluid connections.

Guidelines from the Open Compute Project indicate that a 1 mm mechanical misalignment at a liquid cooling interface can increase flow resistance by approximately 15%, raising pump energy consumption by around 7%. In large installations with thousands of interfaces, these losses directly affect power usage effectiveness (PUE) and operating costs.

In practice, deviations arise from several sources: cumulative rack installation tolerances in mixed EIA-310-D and Open Rack V3 deployments, vibration during transport and operation, and thermal expansion of metal manifolds under temperature swings of 50 °C or more. Conventional rigid connectors, typically limited to ±0.5 mm static tolerance, are not designed to accommodate these combined effects.

Blind mate floating mechanism: technical approach

Southco’s blind mate floating mechanism is designed to decouple sealing performance from precise mechanical alignment. The system allows connection without direct visual alignment, supporting automated deployment and service operations in dense rack environments.

The floating structure provides multi-axis compensation, absorbing radial misalignment and axial displacement caused by installation variation, vibration, and thermal expansion. A self-centering feature returns the interface to a neutral position when disconnected, preserving available tolerance for repeated mating cycles and supporting compatibility with Open Rack V3 requirements.

Sealing performance is qualified against ASME B31.3 pressure criteria, including burst pressure testing at 300 psig, targeting long-term operation in continuous duty data center environments. The design is intended for use in cold-plate and rack-level manifold architectures where repeated connect–disconnect cycles are expected during server replacement or upgrades.

Operational implications for digital infrastructure

By reducing flow resistance penalties associated with misalignment, floating blind mate interfaces can lower pump energy demand and contribute to improved PUE in liquid-cooled facilities. Tool-less blind connection also shortens maintenance windows, enabling faster server swaps and reducing downtime risk in 24/7 operations.

The mechanism supports modular expansion and mixed-vendor environments aligned with open hardware standards, an increasingly important requirement as data centers scale AI and accelerated computing capacity.

Position in the evolving cooling ecosystem

Industry roadmaps for Open Rack V3 architectures project liquid cooling penetration exceeding 40% in hyperscale data centers. Within this context, floating blind mate interfaces address a specific but critical layer of the cooling stack: the mechanical reliability of fluid connections under real-world tolerances.

Southco indicates ongoing development in materials, including high-performance thermoplastics, and future integration of sensing capabilities for flow and temperature monitoring, aligning mechanical interface design with broader digital supply chain and infrastructure observability requirements.

Conclusion

As liquid cooling becomes a structural element of next-generation data centers, connection interfaces are shifting from passive components to performance-critical systems. Blind mate floating mechanisms represent a response to measurable efficiency losses and reliability risks observed in large-scale deployments, providing a mechanical foundation for stable, energy-efficient operation in high-density computing environments.

www.southco.com