www.industry-asia-pacific.com

16

'17

Written on Modified on

NSK ball screws enhance performance of injection moulding machines

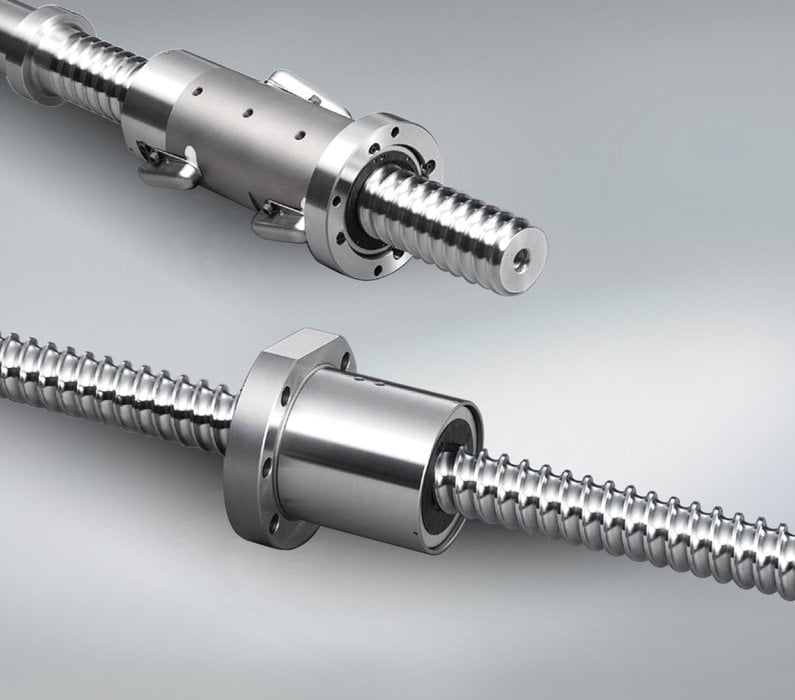

In order to deliver spindle drive service life optimisation in injection moulding machines, NSK has developed several new high-load ball screws, including the latest S-HTF series. However, many well-known manufacturers of injection moulding machines also use NSK's high-load ball screw drives for the clamping and injection axes, which is where the established HTF series is proving popular.

Partly as a consequence of government regulations, injection moulding machines featuring electric instead of hydraulic drives have become established in Japan much earlier than in Europe. NSK has hence seized the advantage gained from this early experience to develop ball screws capable of providing drive optimisation for the clamping axes.

The benefits offered by HTF series ball screws are best illustrated using an example from NSK's recent consulting work. The company is often contacted by machine OEMs for cause analysis, and to recommend long-term technical solutions for machine failures. In a recent case involving a range of injection moulding machines, the ball screw drives serving the clamping axes were failing very prematurely, despite the supplier claiming that they were designed to last for several years.

NSK experts for linear technology at the company’s European Technology Centre (ETC) in Ratingen, Germany, performed a comprehensive inspection of the ball screw drives that led directly to the cause of the failures: under high load, contact was occurring between ball bearings when rotating in opposite directions. The led to friction, which in turn damaged the balls and created a mixture of grease and hardened steel. Ultimately, further damage occurred to the component when rolling, causing the axis to fail completely.

To overcome this problem, which is well-documented behaviour in high-load linear motion applications, NSK had some years earlier introduced S1 technology for use in all HTF high-load ball screw spindles. This patented ball alignment feature stops the occurrence of direct ball-to-ball contact, even in unfavourable conditions.

HTF series drives duly replaced the existing ball screws at the machine OEM on a test basis. Wear was then monitored every week by measuring the metal content present in the grease. Following a period of service that was twice as long in comparison with the previous drive, no wear was ever found. This example demonstrates yet again how HTF ball screws are extremely well suited to clamping axis drive applications on injection moulding machines.

The HTF series was first introduced in 1996, since when spindle types for high-speed injection (HTF-SRC) and very high clamping force applications (HTF-SRE) have been added to the original base product range. S-HTF series ball screws are the latest addition, which offer more than double the service life and 1.3 times greater dynamic load capacity than the company’s previous-generation product. These performance attributes have been achieved thanks to the use of a new steel material (named Tough Steel – TF) for the screw shaft and nuts that delivers an optimised combination of hardness and resilience.