MOVING TOWARDS CLIMATE NEUTRALITY

Fuel cell technology for future energy and propulsion systems.

The first fuel cell module is currently being tested on the test bench at Rolls-Royce Power Systems. Based on these fuel cell modules from automobile production, a demonstrator is being developed which will contribute to the energy supply of Rolls-Royce Power Systems at its headquarters in Friedrichshafen.

1. Introduction

Under the Paris Agreement, all parties have committed to keep global warming well below 2°C, with further efforts being made to limit the temperature rise to 1.5°C. The benchmark temperatures are from the pre-industrial age. Greenhouse gas emissions are to be reduced across the world, and countries particularly affected by climate change are to be aided in dealing with the consequences. The signatories, which include almost all the major industrialized nations, are tasked with drawing up and implementing national climate protection plans. By 2025, the industrialized nations intend to make 100 billion US dollars per annum available for climate protection measures in developing countries. In addition, the European Union has adopted the so-called Green Deal, under which it intends to play its part in global climate protection. This envisages that by 2050 the EU will work, do business, travel, drive and live climate-neutrally.

To thwart the rise in temperature, one of the most urgent tasks is to decarbonize the global economy, moving towards making it carbon-neutral. In addition to the industrial and energy sectors, the focus here is on mobility, whether by car, truck, train, plane or ship.

Besides greenhouse gas emissions CO2 and methane, other pollutant emissions such as nitrous oxides, sulfur dioxide and particulate matter, which are produced during the combustion of fossil fuels, are also to be continuously reduced. It is therefore important to make alternative fuels available in the near future through the expansion of renewable energies and Power-to-X technologies, to prepare combustion engines for alternative fuels and to develop alternative energy and propulsion systems with fuel cells.

2. Zero-emissions fuel cell technology – a logical step forward

For many decades now, Rolls-Royce Power Systems has been a by-word for first-class energy and propulsion solutions, and for the provision of comprehensive support for its products throughout their full life cycles. Developing and implementing technological innovations, and making selective use of the advantages offered by digitalization are the driving forces that make it possible to offer a sustainable portfolio of offerings. The energy and propulsion systems of the future must play their part as solutions to climate change. This needs to be achieved while meeting the social needs of increasing energy usage, the demand for mobility and rising energy requirements driven by world population growth. Electrification of propulsion systems as a possible route towards resource conservation and environmental friendliness calls for products that are robust and at the same time flexible, cost-efficient and scalable.

The Rolls-Royce Power Systems “Green & High-Tech” programme focuses on the development of new technologies and systems that support or deliver decarbonization, whether through alternative fuels, electrification or digitalization. It is always integrated system solutions that are best able to reconcile the ecological aspect with the economic necessities. The Green & High-Tech programme is part of the Power Systems 2030 strategy which sets out the planned route to becoming a provider of sustainable system solutions. Even now, clean, technologically advanced solutions from Rolls-Royce Power Systems are being used in infrastructure and marine sectors across the world.

With this in mind, it is only logical for Rolls-Royce Power Systems to grow its portfolio to include fuel cells, and to gradually extend its development activities to include a variety of application areas. The potential of fuel cell technology is convincing, as is hydrogen as a storage medium within an overall energy system. Strong arguments for using and promoting this technology are high reliability, scalability and the ability to use renewable energy sources. With their modular design, fuel cell systems are easily adaptable to match output with demand, and their low maintenance requirements and low running costs also make them attractive. Futhermore fuel cell technology is ready to be brought to market and suitable for commercial use. The rapidly developing market offers good growth opportunities for zero-emissions fuel cell technology

3. Fuel cells – a key component in the green energy revolution

Fuel cells work differently compared to combustion engines. They convert a fuel's chemical energy directly into electricity which can then be used to drive a growing number of electrified systems. This conversion is more efficient than with combustion engines, as the intermediate thermo-mechanical steps required with conventional energy converters (heat engines) are eliminated. The greatest plus point arises when the fuel used is regeneratively produced hydrogen because it allows both pollutant and climate-damaging gas emissions to be reduced to zero. In this way, fuel cells have an enormous potential to become an essential technology component for decarbonizing propulsion and energy systems.

4. PEM – the fuel cell of choice

The low-temperature proton exchange membrane fuel cell or PEM (sometimes called polymer electrolyte membrane fuel cell) currently represents the most suitable technology for developing and growing the Rolls-Royce Power Systems portfolio. This low-temperature fuel cell has a high-power density enabling even small units to achieve sizeable outputs. Low-temperature fuel cells have operating temperatures of up to around 100 degrees Celsius, posing minimal hazards to both materials and people, while high-temperature fuel cells reach 250 to 1,000°C. The PEM has good load following characteristics as opposed to other types, allowing it to respond to changes of power requirement within seconds. One advantage of the compact PEM fuel cell is its very high electrical efficiency, especially at part load. They typically run on a hydrogen fuel source however they can operate on a wide variety of hydrocarbon fuels (e.g. methanol, diesel or natural gas). This is achieved by using well known reforming techniques to convert them into hydrogen. This gives PEM fuel cells a very wide-ranging field of application.

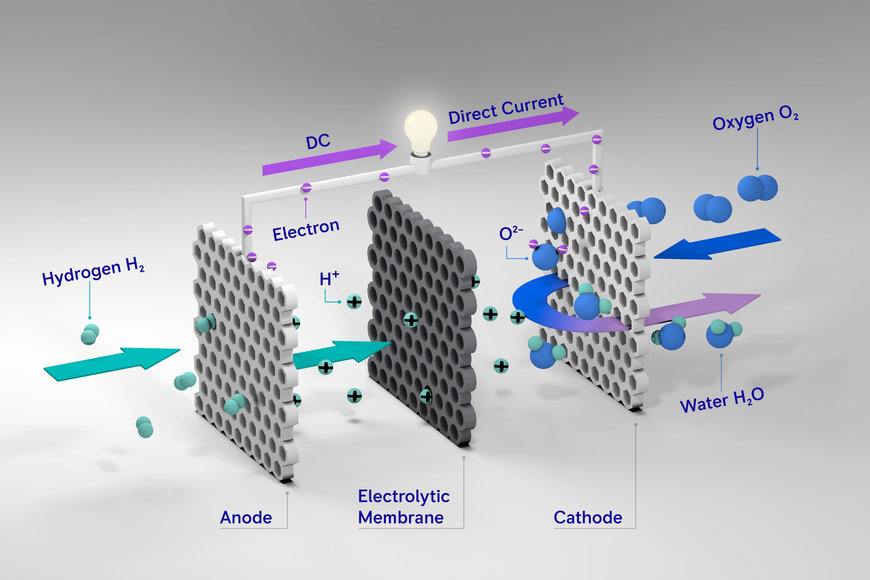

How a PEM fuel cell works

The fuel cell is a galvanic cell that electrochemically reacts fuel and an oxidant (usually air) to produce electricity and exhaust products. It works quietly and without much in the way of vibration. Similar to batteries, fuel cells also generate direct current voltage. However, unlike batteries fuel cells require a constant inflow of fuel and oxidant.

With a PEM fuel cell, a chemical process takes place between the electrodes (anode and cathode) in which the positive ions (protons) migrate from anode to the cathode, and the electrons are conducted externally from the anode to the cathode via an electrical conductor. The product of this process is electrical power that can be withdrawn and used. The electrodes are coated with a platinum or palladium catalyst and separated from each other by an electrolyte. Without the catalyst, hydrogen and oxygen would not react to produce heat and electricity. The electrolyte consists of an ion-conducting membrane, and it is important for this membrane to be permeable for protons and impermeable to electrons.

The name “polymer electrolyte membrane fuel cell” indicates that the membrane is a key feature of this fuel cell. This is usually made of plastic and is similar to Teflon. The water-saturated polymer membrane, which serves as an electrolyte, allows only protons – the positively charged atomic nucleus of hydrogen – to pass from anode to cathode. The water content of the membrane required for this ion conduction is responsible for limiting the operating temperature to a maximum of 100°C.The amount of precious metal (e.g. platinum) required for the catalyst has been steadily reduced in recent years. This has already led to a significant reduction in costs and remains the focus of development efforts.

For Rolls-Royce Power Systems applications, the PEM fuel cell is ideal thanks to the high-power density, high scalability, modular design capability and resultant flexibility. Fuel cells can, for example, be built directly into battery-powered or electrified energy systems. The cell achieves high electrical efficiency (around 50%) and high current density, and is also very safe to use. This makes it suitable not just as a source for stationary power– say in the form of an emergency generator or an uninterruptible power supply – but also ticks all the boxes for mobile use aboard ships.

In order to increase the power density even further, today's fuel cell systems sometimes feature air compressors or even electric turbochargers. As with internal combustion engines, the compressors or turbochargers pump air into the air system at a pressure of 2 to 3 bar. Several individual fuel cells can be connected in series to form a stack, thus increasing the voltage. To achieve more performance, the stacks can also be connected in parallel. This increases the amount of current generated to multiples of that achieved by serial connection.

In developing and applying fuel cell technology, Rolls-Royce Power Systems draws on in-depth expertise and years of experience. Between 1999 and 2011, 26 high-temperature fuel cell systems – molten carbonate fuel cells (MCFCs) – have been installed and successfully operated in various areas of application. The combination of electricity and pressurized steam is used in a wide range of processes in industry and in the health sector. The systems have run an average of around 22,000 operating hours, and all performance data and empirical values have been recorded and analyzed. While market conditions and the general framework at that time did not support full production, all lights are now green for introducing PEM fuel cells into mass-market settings as an alternative source of drive power.

BENEFITS OF FUEL CELLS AT A GLANCE

- High electrical efficiency (around 50%, compared to around 40% from diesel gensets)

- When run on pure hydrogen, no emissions except water vapor – no carbon dioxide, and no nitrous oxides or particulate matter

- Low-noise operation

- Low-maintenance technology (no moving parts in the fuel cell stack)

- No vibrations

- Key technology for independent distributed energy systems

- Key technology for long-range electric mobility with high power requirements and short refueling times

- Climate-neutral when generating using renewable energy sources or when run on “green” hydrogen

5. Examples of use

5.1 Emergency power solution for data centers

Their characteristic features mean PEM fuel cells are suited to various applications currently powered by combustion engines. Among other things, fuel cells could play a key role in zero-carbon data centers.

Data centers are part of the worldwide safety-critical infrastructure which includes hospitals, airports and telecommunications, and it is essential that it operates absolutely trouble-free. In the event of a power failure, current solution is usually for diesel generator sets to supply power to the data center until normal operation is restored. MTU emergency power gensets meet the highest exhaust emission standards and offer maximum reliability with minimum maintenance, yet the combustion of fossil fuel (diesel) inevitably results in exhaust gas emissions.

If fuel cells are used for backup power supply – be it in the form of an uninterruptible power supply (UPS) or a mains backup system (MBS) – the only things given off are heat and humid spent air. The fuel cell system has no moving parts, which minimizes mechanical maintenance. The fuel cell also wins on efficiency. Whereas, with a combustion engine, mechanical energy has to be converted into electricity using an additional generator, the fuel cell supplies electricity without any extra equipment. A further advantage is that it can be scaled with ease. More modules mean more power, and fuel cell systems can easily be added later and grow with the data center. This makes fuel cell systems a long-term, future-proof investment.

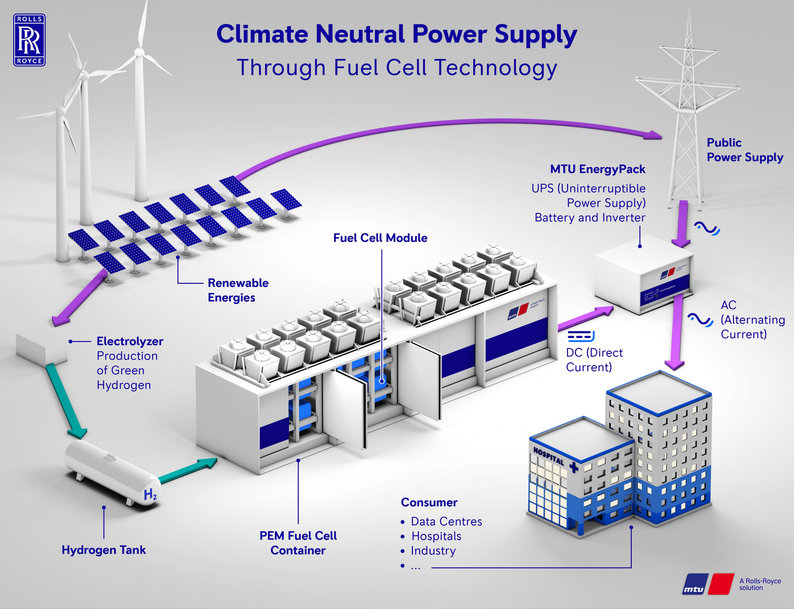

The following scenario demonstrates the use of fuel cells as an integral part of zero-carbon data center that emits no pollutants:

In future, the basic power requirements of a data center could be covered by solar and wind power plants. If sufficient “green” electricity were available, hydrogen could be produced from water by electrolysis and stored on site. Alternatively, the hydrogen requirement for powering the fuel cell could be covered by a supply network that will be in place in the future. In the event of a power failure, it would immediately step in to supply the data center and avoid infrastructure outages.

Rolls-Royce Power Systems will make fuel cell technology available to its customers in future.

To provide a zero-carbon, pollutant-free standby power solution, up to six modules will be integrated into a fuel cell system. The modules will consist of stacks featuring several hundred fuel cells and the supply lines for air, hydrogen and cooling. The modular design will make it possible to adapt output to requirements. Up to 24 modules can be installed in one FC container.

Rolls-Royce Power Systems is aiming to offer an integrated, fully-featured emergency power solution. This will include the fuel cell system, a UPS system, batteries and the hydrogen infrastructure. The solution will be black-start-capable, i.e. able to resume generation without intervention, and deliver more than two MW of power.

The cost-effectiveness of the fuel cell can be increased in future by storing the surplus electricity produced and using it at peak load times. An alternative option is to feed 20% to 30% of the electricity generated into the grid and thus benefit from the distributed feed-in tariff. In addition to the economic benefit, this will relieve pressure on the overall grid and reduce power peaks.

Rolls-Royce and Daimler Truck AG are planning to collaborate on a carbon-neutral emergency power supply for safety-critical facilities such as data centers using stationary fuel cell generators. These are intended to offer emission-free alternatives to diesel engines, which have so far been used as emergency power generators or for covering peak loads. Daimler Truck AG and Rolls-Royce have signed a letter of intent to this effect. At the end of 2019, Rolls-Royce Power Systems and Lab1886, Daimler's innovation unit for new business models, had already agreed on a pilot project to develop a demonstrator for the use of this technology for stationary power supplies using fuel cell modules from automobile production. It will go into operation at the beginning of 2021 and feed into the power supply system at Rolls-Royce Power Systems' headquarters in Friedrichshafen.

5.2 Demand response

A high degree of flexibility is required for the increasing use of renewable energy sources, because generation and demand have to be balanced, and security of supply cannot be compromised. Especially in Central Europe, the sun does not shine all the time and wind power is also limited by weather patterns. So there are times when, by nature, not enough green electricity can be produced to meet all demands. Equally, there are times when more power is generated from renewables than is needed at that moment. In such a case, it is important, firstly, for consumers to be able to react quickly and reduce demand immediately, possibly for a longish period of time. Secondly, power suppliers have to be able to supply (more) electricity at short notice or reduce their supply. Surplus electricity can also be stored in the form of hydrogen and, if required, made available again at short notice in the form of electricity with the aid of a fuel cell system. This load management or “demand response” activity using smart grids will be one of the key factors for converting energy systems to sustainable methods of production.

A demand response solution using PEM fuel cells in combination with batteries is ideal for stabilizing grids and cushioning power peaks. Consumers can use the system to cover their requirements even when generation output from renewables is low. The PEM fuel cell generator offers the ability to be connected to locally operating systems or to what are referred to as “microgrids”.

5.3 Onshore power

Ports and harbors suffer from high environmental pollution. This is due to the exhaust fumes not only from shipping traffic, but also from vessels tied up in ports, because these mostly meet their power requirements by running their own on-board diesel generators. This too causes high levels of air pollution and noise emissions, which is a particular burden for local residents when port facilities are located in densely populated areas.

Essentially, it is also possible to source on-board power via a shore connection. However, many ports do not currently have correspondingly powerful shore power facilities for supplying large vessels requiring several hundred kilowatts or even several megawatts of on-board electricity. Alternatively, this shore power can be provided using hydrogen-powered PEM fuel cells – with zero emissions. The silent and entirely emission-free fuel cell system could be built into a container no more than 14 meters long, with cooling systems on the roof and a hydrogen tank. The size of the container solution is similar to that of the existing diesel generators and can easily be built into existing port infrastructure. Here, too, their modular nature means that fuel cell systems can be adapted step-by-step as requirements change.

Ports are the ideal environments for building new fuel-cell supply systems: They are set to be crucial logistical nodes in the hydrogen supply infrastructure, and in fact some are already connected.

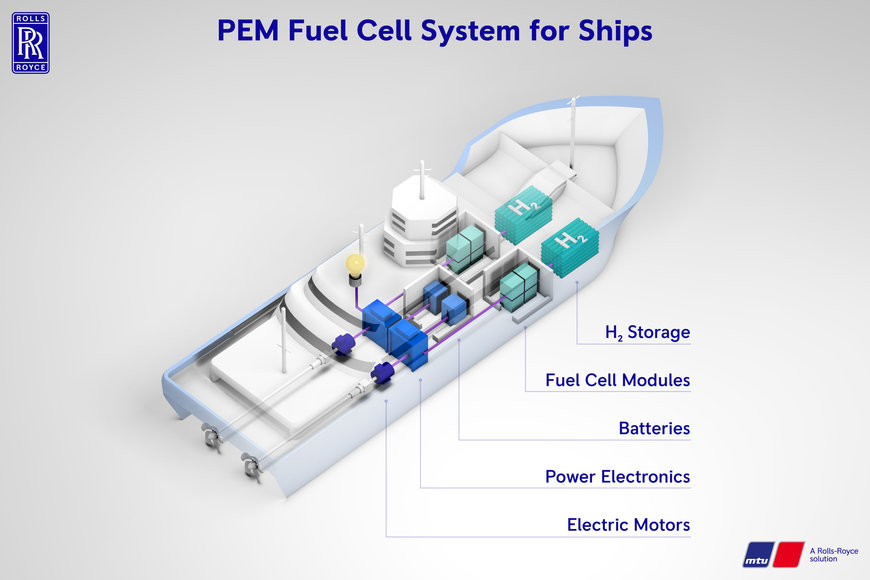

5.4 Fuel cells for marine propulsion systems

Alternative propulsion systems are attractive and necessary not just for cars and trucks, but also for ships. Shipping accounts for 2% to 3% of global CO2 emissions, and this proportion is set to rise significantly by 2050 with the increase in global trade. For Rolls-Royce Power Systems, with its long tradition as a supplier of marine propulsion systems, it is therefore very important to continue offering its customers even more environmentally friendly solutions in future. On-board fuel cell systems combine numerous benefits: As well as their sustainability and environmental friendliness, fuel-cell-based marine propulsion systems are gaining favor due to their high level of passenger comfort and high modularity. They are quiet, they produce no smelly exhaust gases, and they are virtually vibration-free. This emission-free propulsion system enables vessels to be used in sea, lake and river areas where other systems are outlawed due to nature and environmental protection requirements.

A fuel cell marine propulsion system is made up of several parts. At the heart of the system is the fuel cell, which converts hydrogen into electricity. This power is fed via the on-board electrical distribution system to large consumers such as the electric motors driving propellers and winches and also to the smaller “domestic” consumers. The on-board distribution system also features a power storage device – typically a (lithium ion) battery – to store power temporarily. This battery permits a time lag between generation and consumption of power, thus opening up the possibility of timing the operation of individual components for maximum efficiency. This calls for a smart power management system for controlling individual components.

Hydrogen-powered fuel cell systems are suitable for use on inland waterways, such as lakes and fjords, and for coastal navigation and use in port ferries. Since the vessels can be regularly refueled on land the routes to be covered are feasible using current state-of-the-art technology. One of the challenges in opening up this market is that the required hydrogen must be carried on board in sizeable tanks, in either gaseous or liquefied form. The current lack of infrastructure means reliable hydrogen supplies are a major consideration. Increased safety requirements also call for technical solutions for the safe handling of fuel on board. The integration of fuel cell systems on board must also be planned carefully meeting specific marine requirements. Methanol is also a potential fuel for PEM fuel cells in marine applications. The methanol is reformed, i.e. converted into hydrogen, before use in the PEM fuel cell. The big advantage here is that methanol tanks take up less space than the equivalent hydrogen ones, thus enabling longer refueling intervals and greater ranges.

In order to solve these challenges and take fuel cell propulsion systems to the next level, Rolls-Royce Power Systems believes it is important to engage in a process of interdisciplinary, cross-industry networking and sharing. For this reason, the company is open to all potential partners and interested parties, and is already in discussions with a variety of technology partners. In specific terms, Rolls-Royce Power Systems is helping shipbuilders and vessel operators pinpoint solutions for their individual requirements.

6. Outlook

Fuel cell technology is increasingly gaining traction in view of pollutant emissions and climate protection requirements. When it comes to making best use of renewables for low-emission, zero-carbon production of electricity and heat, the fuel cell, compared with other systems, is the front-runner in terms of efficiency, making it an attractive proposition for a variety of applications. Even today, fuel cells can be used to ensure efficient energy supply within stationary stand-alone facilities, as well as their mobile use powering land vehicles and ships.

The big advantage of hydrogen-powered fuel cells is that CO2 emissions, whether from vessels or stationary power plants, reduce to zero where green hydrogen is used. The hydrogen strategies that have been presented by for example the EU Green Deal and the German Government's National Hydrogen Strategy, indicate that infrastructure expansion is on the political agenda and is being tackled with vigor.

Rolls-Royce Power Systems is driving forward future technologies for the marine and infrastructure sectors with its newly founded “Power Lab” unit. Centers of emphasis include fuel cell systems and the production and use of synthetic fuels. The aim is to serve the trends in the markets pro-actively, and to grow the portfolio of offerings adding new energy and propulsion solutions for a climate-neutral future.

Excursus: Hydrogen – a near limitless source of energy

Hydrogen has the benefit of being available in almost unlimited quantities – albeit always chemically combined with other elements. The largest usable deposit of hydrogen is bound to oxygen in the form of water. Whether in liquid or gaseous form, hydrogen is colorless. When referred to as green, grey, blue and turquoise this refers to the method of production and the associated direct and indirect CO2 emissions. Ideally, only green hydrogen is used as fuel in PEM fuel cells, ensuring the power generation process is entirely pollutant-free. Until large quantities of hydrogen can be produced from renewable energy sources, other routes are being looked into. In developing fuel cell drive systems, Rolls-Royce Power Systems is investigating all the options, always with a view to keeping the hydrogen production as carbon-neutral as possible.

SHORT GUIDE TO HYDROGEN COLORS

Green hydrogen is primarily produced by water electrolysis, using only electricity from renewable energy sources. Furthermore, green hydrogen can also be produced by gasification and fermentation of biomass and reforming of biogas. The key thing is for all manufacturing processes to be carbon-neutral.

Grey hydrogen is obtained from fossil fuels. The most common process is steam reforming, which converts natural gas and steam under heat into hydrogen and CO2. The production of one metric ton of hydrogen generates around 10 metric tons of carbon dioxide, which is usually released unused into the atmosphere.

Blue hydrogen corresponds to grey hydrogen as far as the raw material and manufacturing process are concerned. However, with blue hydrogen, the CO2 produced is stored (carbon capture and storage, CCS) sometimes injected under the seabed. Although no CO2 is vented to atmosphere using this method, this hydrogen produced is not entirely carbon-neutral as climate gases still escape into the environment during production and transportation.

Turquoise hydrogen is the result of methane pyrolysis, which thermally splits methane into solid carbon and hydrogen. Instead of CO2, solid carbon is produced in the process. This hydrogen is not entirely carbon-neutral, as climate gases still escape into the environment during production and transportation.

How safe is hydrogen?

Hydrogen is invisible, odorless, non-toxic, non-corrosive and non-hazardous to water. Nor does it ignite by itself, but when mixed with air it is an ignitable gas over a wide range of concentrations, 4% to 75% by volume. With this in mind, hydrogen must be produced, stored, transported and used safely. One specific property of hydrogen is its high volatility. This is a great advantage, because the risk of explosion decreases rapidly at a certain mixing ratio with air. The hazard potential of hydrogen is comparable to that of natural gas. Safety precautions are designed accordingly, and handling is regulated by a comprehensive set of standards. European industry can now draw on comprehensive infrastructure expertise, not least thanks to special hydrogen pipelines totaling over 1,500 km in length.

Without oxygen, hydrogen is non-explosive. Storage in tanks is therefore not dangerous in itself. Safety valves ensure that the hydrogen is blown off in a controlled manner at overpressure and volatilizes. Escaping hydrogen can be ignited and flared by an ignition source without causing an explosion.

In 2021, Rolls-Royce Power Systems will commission a demonstrator with hydrogen-powered fuel cells for power generation on the factory premises in Friedrichshafen and will use it to test, among other things, safety precautions under a wide range of conditions. The demonstrator will meet all explosion and fire prevention criteria as well as current building regulations. Rolls-Royce Power Systems will install a multi-stage safety system that first prevents leakage, then automatically shuts down and ventilates. The fuel cell systems are designed in such a way that the hydrogen cannot come into contact with the ignition sources.

International hydrogen strategies

The funding provided by the German Federal Government and the European Union, and the worldwide efforts of numerous governments and companies to advance fuel cells and their associated technologies provide Rolls-Royce Power Systems with an ideal environment in which to develop its own system solutions based on fuel cells.

There is a consensus in Europe that hydrogen is to become competitive by 2030 in order to secure the green energy revolution in Europe, and to meet the common goal of becoming carbon-neutral across all sectors within 30 years. It is planned to increase production of hydrogen from renewables, with financial support, to up to a million metric tons by 2024 and ten million metric tons by 2030. To this end, electrolyzers with a capacity of at least 6 gigawatts are to be built in the EU by 2024, increasing to 40 gigawatts by 2030. The European Clean Hydrogen Alliance founded by the EU Commission supports this strategy.

With its national hydrogen strategy, Germany aims to become a pioneer in the production and use of hydrogen. Climate-neutrally produced hydrogen is considered a sustainable approach to operating heavy trucks, ships and industrial processes. However, resources from renewable energies in this country are not yet sufficient for producing hydrogen in the quantities required. Alliances with third parties were therefore agreed within the framework of the National Hydrogen Strategy.

It is planned to dedicate 9 billion euros to aiding production and application of hydrogen. The German government's strategy envisages the construction of production plants with a total capacity of up to five gigawatts by 2030, including the necessary wind turbines. Electrolysis capacities of ten gigawatts are to be created by 2040 – a capacity roughly equivalent to that of ten nuclear power plants.

In 2017, Japan became one of the first countries in the world to merge the existing hydrogen projects of its car and technology companies into a dedicated national hydrogen strategy. The goals are ambitious, the country wants to establish a global supply chain and a sizeable market for hydrogen by the year 2030. Plans include 800,000 fuel cell vehicles and 5.3 million stationary fuel cells for hot water and electricity generation in the residential sector.

In the field of fuel cell development, companies and associations in China are entering into a large number of national and international collaborations. For example, Weichai Power, China's largest engine maker, is set to invest over 5 billion euros in fuel cell development by 2030 and is collaborating with Ballard and Bosch to do this. At the political level, the National Alliance of Hydrogen and Fuel Cell (NAHFC) was founded in February 2018, an alliance of companies from the energy sector and the automotive industry supported by the Chinese government.

South Korea presented a roadmap in 2019 intended to lead to the country becoming the world market leader in hydrogen technologies. The plan is to put over 6 million fuel cell vehicles on the road by 2040, and to build 1,200 filling stations to ensure energy independence and adopt a leading role in hydrogen technology worldwide.

www.mtu-solutions.com