www.industry-asia-pacific.com

08

'25

Written on Modified on

Digital Twins in Industrial Automation

Digital twins serve as a cornerstone of Industry 4.0, empowering companies to innovate faster, operate smarter, and build resilient, future-ready ecosystems, says Milton D’Silva.

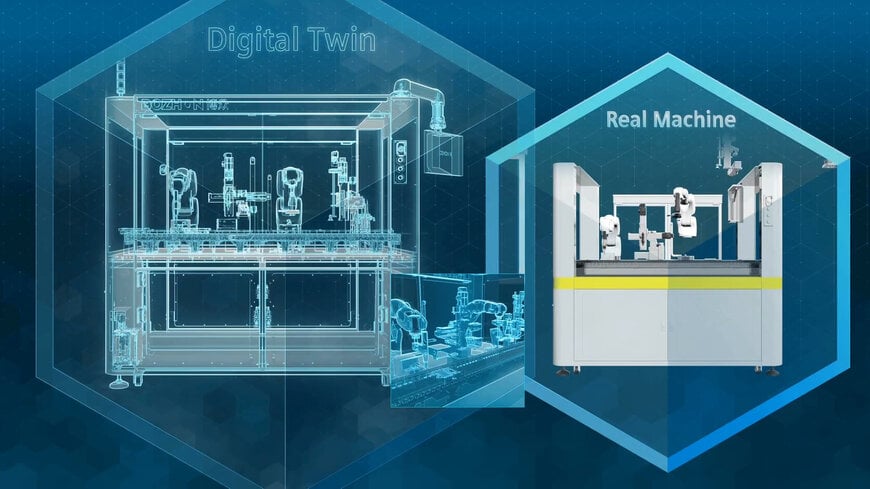

Digital twin is a virtual copy or replica of a real thing. Image source: Siemens

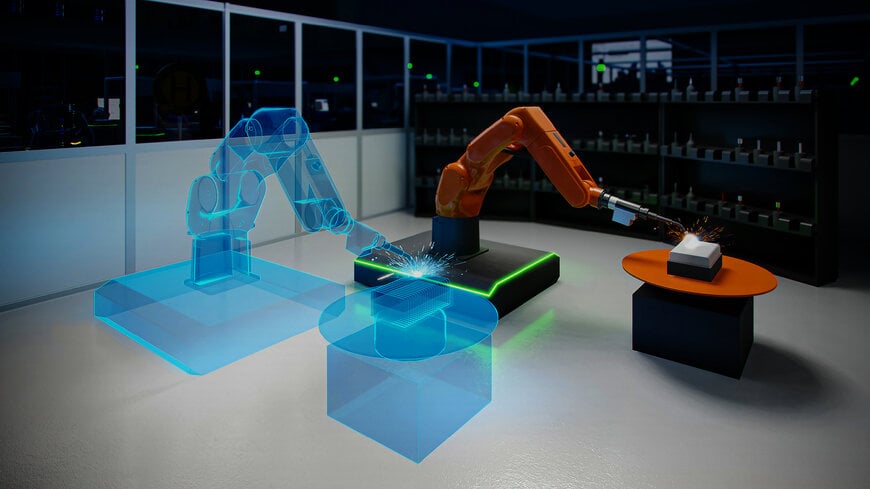

In simple terminology, a digital twin is a virtual copy or replica of a real thing – an object, a factory or plant or building, a process or a system – on a computer. This digital twin is not just a drawing or a 3D model – it is in fact a multi-dimensional graphical representation that behaves like the real thing of which it is a replica. The digital twin is connected to the real object or process through sensors and IoT devices and is an interactive model in the sense that changes made on one are reflected in the other or mimicked by it. To draw a simple analogy, it is like a video game of a race car where a real car is connected by sensors to the virtual replica on the screen which is manipulated by the player.

Though the term digital twin first appeared in the records of NASA only in 2010, the American space agency was using the concept right from the 1960s in connection with the Apollo programme, when two identical models were built of the spacecraft to study their behaviour and maintain a record of the actual performance during the missions. It is the aerospace and aviation industry that has been at the forefront of exploring and developing the concept of digital twin further over the next three decades. In 1989, when Boeing was developing the 777, it was the first time a ‘digital mock-up’ of the entire aircraft was created using Dassault Systèmes’ Catia software. The digital mock-up allowed for virtual design, simulation, and testing of the aircraft before physical prototypes were built, opening a new era of paperless aircraft design. Much later, talking about the experience, Bernard Charlès, the then Vice Chairman and CEO, Dassault Systèmes, said, “In 1989, we created the first virtual twin of a giant airplane, the Boeing 777.”

Dassault Systèmes, is one of the major exponents, but calls them virtual twins. Image source: Dassault Systèmes

Today, digital twins are regarded as one of the pillars of industrial automation in the Industry 4.0 era, and are not only helping in design and development of products and plants, but also provide a virtual mirror of physical assets, facilitating real-time monitoring of their performance and status. Digital twins are also the most important of the core technologies that constitute the industrial metaverse, the emerging ecosystem for next-gen manufacturing. Among the leading vendors of digital twin technologies are global automation companies like ABB, Ansys, AVEVA, Bosch, PTC, Rockwell Automation, and Siemens. These are just a few names, and there are scores of other companies including Bentley Systems, Cisco, IBM, Microsoft, NVIDIA, Holo-Light, QIO Technologies, etc., with platform services and more. This article examines the role of digital twins in industrial automation in all its aspects.

Understanding digital twins

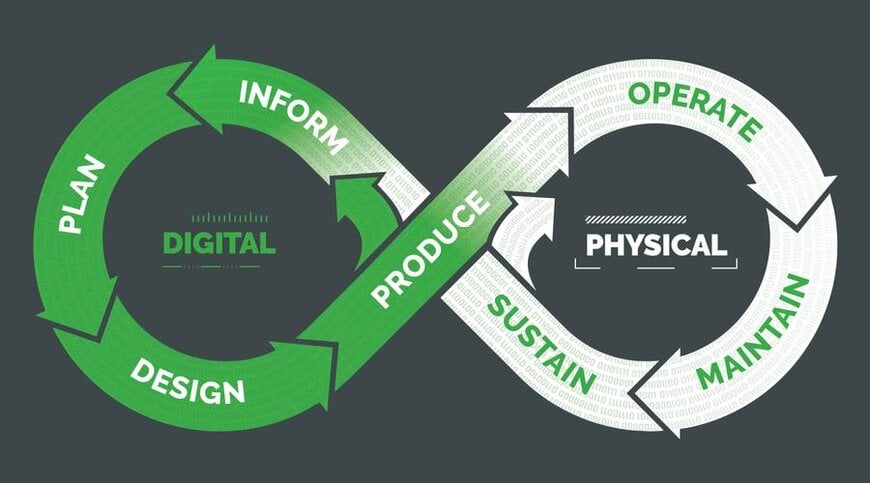

The opening sentence of this article explains what a digital twin is, in very simple terms. However, for professionals in the automation industry, a digital twin is more than a virtual replica of an object or process. It may be defined as a dynamic, virtual representation of a physical asset, process, or system across its lifecycle, continuously updated with real-time data from sensors, simulations, and other sources, enabling monitoring, analysis, prediction, and optimisation of performance. This means the digital twin in actual use in industry enables real-time mirroring of physical assets through data, models, and analytics. It is achieved by a continuous data feedback loop formed by: sensors → data platform → analytics → actionable insights → control action. To be precise, the digital twin must be kept up-to-date with the real-world counterpart, typically via real-time or near-real-time data flow, ensuring the virtual model accurately reflects the physical one.

The basic characteristics of a digital twin are:

In simple terminology, a digital twin is a virtual copy or replica of a real thing – an object, a factory or plant or building, a process or a system – on a computer. This digital twin is not just a drawing or a 3D model – it is in fact a multi-dimensional graphical representation that behaves like the real thing of which it is a replica. The digital twin is connected to the real object or process through sensors and IoT devices and is an interactive model in the sense that changes made on one are reflected in the other or mimicked by it. To draw a simple analogy, it is like a video game of a race car where a real car is connected by sensors to the virtual replica on the screen which is manipulated by the player.

Though the term digital twin first appeared in the records of NASA only in 2010, the American space agency was using the concept right from the 1960s in connection with the Apollo programme, when two identical models were built of the spacecraft to study their behaviour and maintain a record of the actual performance during the missions. It is the aerospace and aviation industry that has been at the forefront of exploring and developing the concept of digital twin further over the next three decades. In 1989, when Boeing was developing the 777, it was the first time a ‘digital mock-up’ of the entire aircraft was created using Dassault Systèmes’ Catia software. The digital mock-up allowed for virtual design, simulation, and testing of the aircraft before physical prototypes were built, opening a new era of paperless aircraft design. Much later, talking about the experience, Bernard Charlès, the then Vice Chairman and CEO, Dassault Systèmes, said, “In 1989, we created the first virtual twin of a giant airplane, the Boeing 777.”

Dassault Systèmes, is one of the major exponents, but calls them virtual twins. Image source: Dassault Systèmes

Today, digital twins are regarded as one of the pillars of industrial automation in the Industry 4.0 era, and are not only helping in design and development of products and plants, but also provide a virtual mirror of physical assets, facilitating real-time monitoring of their performance and status. Digital twins are also the most important of the core technologies that constitute the industrial metaverse, the emerging ecosystem for next-gen manufacturing. Among the leading vendors of digital twin technologies are global automation companies like ABB, Ansys, AVEVA, Bosch, PTC, Rockwell Automation, and Siemens. These are just a few names, and there are scores of other companies including Bentley Systems, Cisco, IBM, Microsoft, NVIDIA, Holo-Light, QIO Technologies, etc., with platform services and more. This article examines the role of digital twins in industrial automation in all its aspects.

Understanding digital twins

The opening sentence of this article explains what a digital twin is, in very simple terms. However, for professionals in the automation industry, a digital twin is more than a virtual replica of an object or process. It may be defined as a dynamic, virtual representation of a physical asset, process, or system across its lifecycle, continuously updated with real-time data from sensors, simulations, and other sources, enabling monitoring, analysis, prediction, and optimisation of performance. This means the digital twin in actual use in industry enables real-time mirroring of physical assets through data, models, and analytics. It is achieved by a continuous data feedback loop formed by: sensors → data platform → analytics → actionable insights → control action. To be precise, the digital twin must be kept up-to-date with the real-world counterpart, typically via real-time or near-real-time data flow, ensuring the virtual model accurately reflects the physical one.

The basic characteristics of a digital twin are:

- Dynamic & virtual – It’s not a static model; it evolves as the physical counterpart changes.

- Covers assets, processes, and systems – Applicable from a single machine to an entire supply chain.

- Lifecycle perspective – Starts at design, continues through operation, maintenance, and end-of-life.

- Data-driven – Real-time or near-real-time data integration is essential.

- Action-oriented – The purpose is not just to mirror reality but to monitor, analyse, predict, and improve outcomes.

Enabling technologies

At this point it would be very relevant to pause and consider the technologies that enable the functioning of the digital twin. The key enabling technologies are:

At this point it would be very relevant to pause and consider the technologies that enable the functioning of the digital twin. The key enabling technologies are:

- IoT and industrial IoT (IIoT)

- Edge and cloud computing

- Artificial intelligence and machine learning (AI & ML)

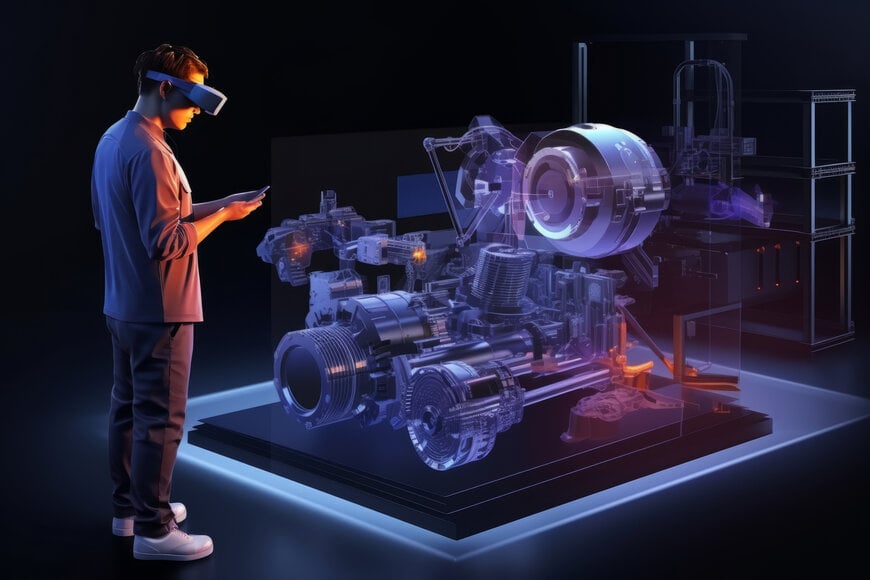

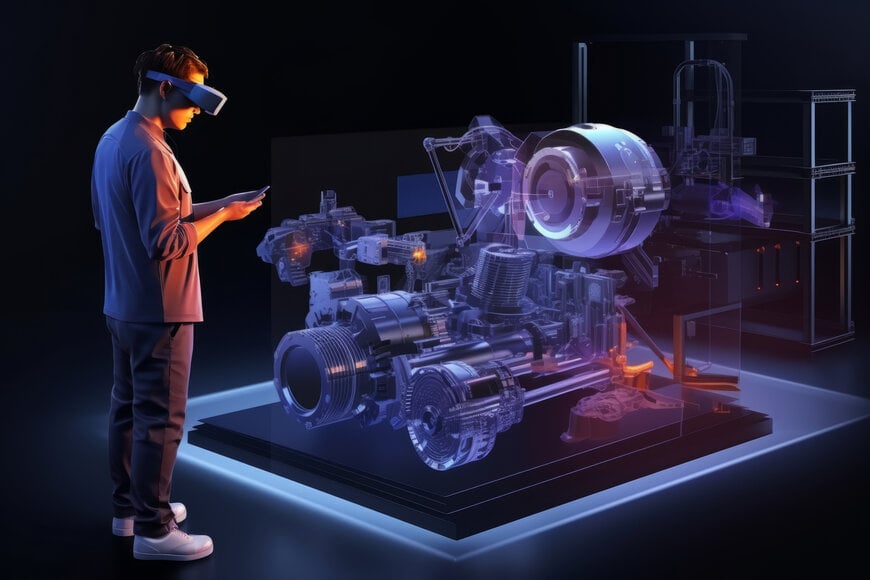

- Extended reality (XR) – an umbrella term for all immersive technologies

- 3D modeling & simulation software, and

- Connectivity standards (OPC UA, MQTT, 5G).

These technologies work together to create a dynamic, intelligent, and trustworthy digital replica of a physical object or system. Internet of Things (IoT) and its industrial sibling, the IIoT provide the real-time data stream from physical assets through sensors, enabling continuous monitoring and feedback for the digital twin. AI and ML are crucial for data analysis, predictive maintenance, anomaly detection, and automated decision-making within the digital twin. Cloud computing provides the scalable infrastructure for data storage, processing, and simulation capabilities needed for complex digital twins. XR technologies allow for immersive interaction with the digital twin, enhancing user experience and facilitating remote collaboration. Advanced modeling and simulation include high-fidelity physics-based models, reduced order models, and surrogate modeling, which are essential for accurate simulations and scenario analysis within the digital twin. And connectivity standards enable seamless communication and data exchange within industrial and IoT systems and devices.

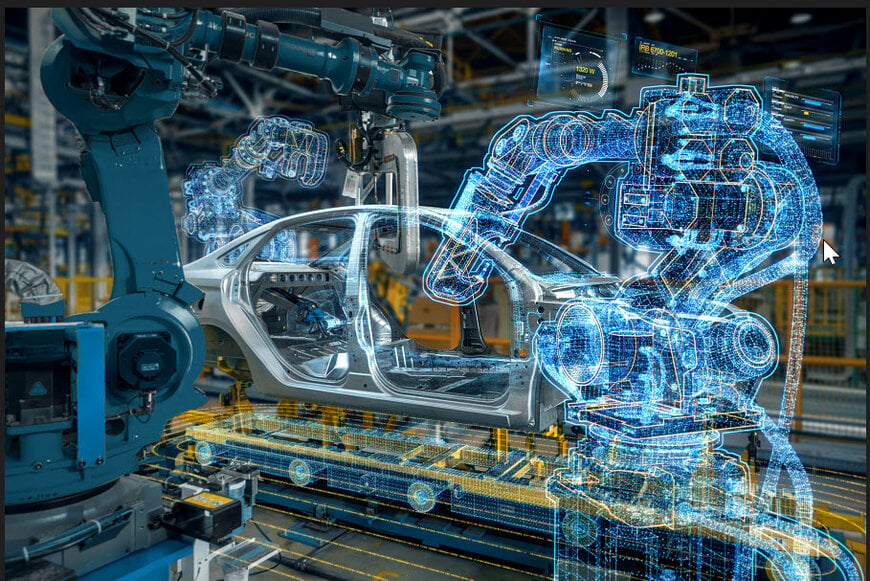

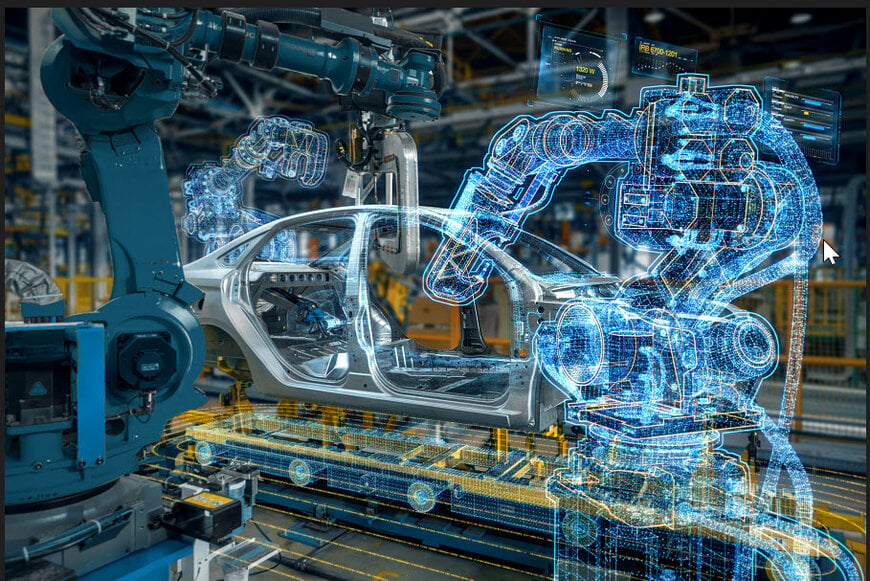

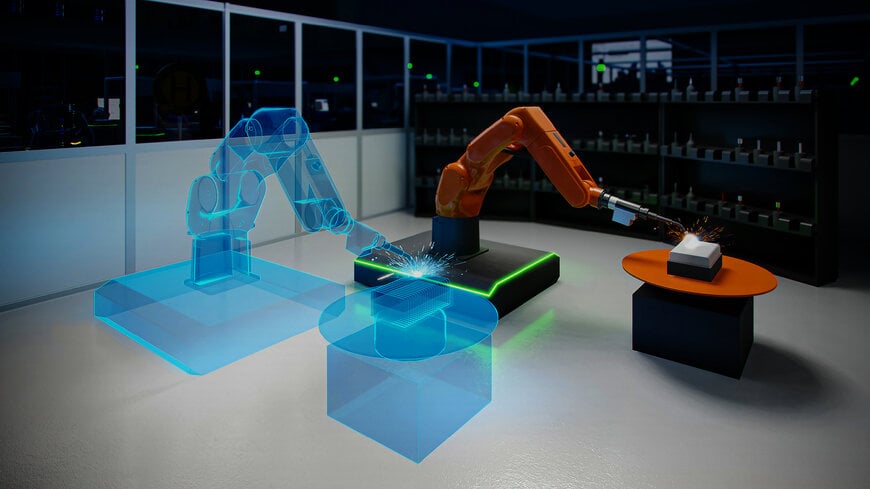

Virtual copies of physical assets make it possible to simulate and optimise workflows and processes. Picture credit: Bosch

Types of digital twins

There are different types of digital twins used in industry, though the basic concept is essentially the same. The difference is in the details, usually based on the scope of their application. The main types of digital twins include:

1. Component/Part Twins: These are the most basic, also the smallest, as they are used only for an individual part or component, rather than the whole machine or system. This type of digital twins relate to properties, condition, and behaviour of a single component, e.g., a cylinder or a piston, a valve, etc., and used for material stress analysis, design optimisation, or early fault detection.

2. Asset Twins: These represent an entire physical asset or piece of equipment, and actually show how various components interact within a specific machine or device, e.g., an engine or a compressor, generator or alternator. They are used for monitoring performance, predictive maintenance, operational optimisation, etc.

3. System/Unit Twins: System or Unit twins represent a group of assets that work together as a functional unit, and capture interdependencies and process flows between multiple assets within a manufacturing or process plant. Their application is for process optimisation in a production line, analysing bottlenecks, etc.

4. Process Twins: These represent end-to-end manufacturing or operational processes and are designed to simulate workflows, production steps, and process dynamics. The idea is to ensure efficiency improvement, scenario testing, throughput optimisation, and the like.

5. Plant/Facility Twins: These are for the full production facility or plant, and integrate multiple system twins to provide a holistic view of operations. They are used for tasks like plant-wide energy management, safety compliance, capacity planning, etc.

6. Network/Supply Chain Twins: As the name implies, these are applied to the entire interconnected supply chain or distribution network, to track product flows, logistics, and demand-supply dynamics. Their purpose is inventory optimisation, risk mitigation, resilience planning.

7. Human-Centric Twins: These digital twins mirror human operators, maintenance crews, or customer interactions, to simulate ergonomics, task execution, and decision-making impact. Obviously, the application of these twins are in matters concerning workforce safety, training, and performance analysis.

8. Hybrid or Composite Twins: These twins combine multiple types, i.e., two or more of the types described above, for integrated insights in specific scenarios. The purpose is to give multi-layered visibility for complex, interconnected systems. Their application is in more advanced cases like smart factory control, or industrial metaverse ecosystem.

Digital twins and industrial automation

Now having understood the basics of digital twins, the next thing to examine is, what purpose do they serve? What are the application areas? But before that, there is also the matter of how are digital twins integrated with the industrial automation ecosystem, more specifically with the PLC/SCADA/DCS environment? This is achieved by using communication protocols like OPC UA and custom APIs to establish bidirectional, real-time data exchange between the physical assets and their virtual models. This allows the digital twin to receive live data for monitoring and simulation, while also sending optimised control strategies back to the SCADA or DCS for validation and execution in the physical world, enabling predictive maintenance, performance optimisation, and virtual testing. Data flows from physical assets to the digital twin, where analytics provide insights into production processes, and these insights are then fed into the MES for real-time shop floor management and the ERP for higher-level business planning, creating a unified and intelligent manufacturing environment.

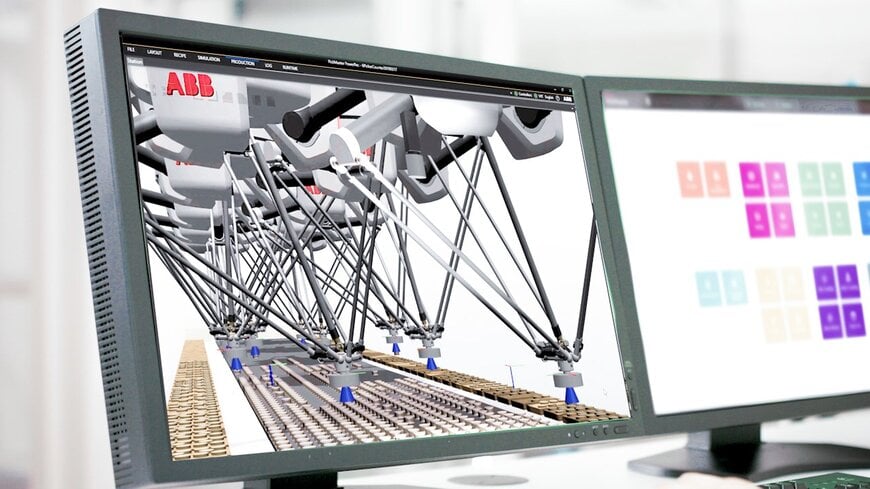

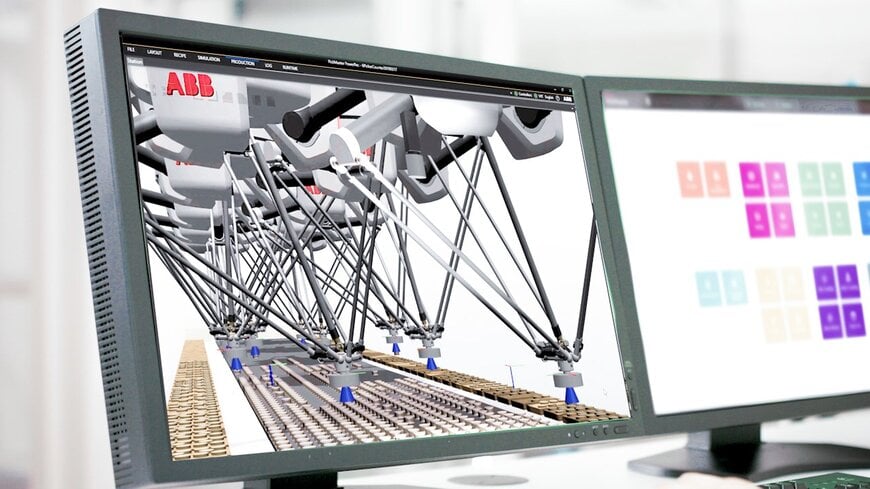

ABB PickMaster Twin, helps reduce commissioning times. Image source: ABB

When it comes to applications in industrial automation, digital twins have many, which are basically focused on optimising processes, enhancing efficiency, and improving overall performance. These objectives are achieved through key areas that include predictive maintenance, system simulation, process optimisation, and quality control. Above all, digital twins play an important role in virtual commissioning as well as operator training and simulation of actual operations. The following paragraphs take a closer look:

1. Predictive maintenance: One of the most cost-effective maintenance practices, digital twins can be used in predictive maintenance to monitor the performance of equipment and systems in real-time, allowing for the prediction of potential maintenance needs. The digital twin can identify anomalies by analysing the data from running equipment and predict when maintenance will be required, enabling proactive and timely interventions.

2. System simulation and optimisation: By simulating the behaviour of complex systems, such as production lines or entire factories, under various conditions, the digital twin allows engineers to test different scenarios, optimise production processes, and identify bottlenecks without disrupting physical operations. By simulating different layouts, workflows, and process parameters, manufacturers can fine-tune their systems for maximum efficiency and throughput.

3. Process optimisation: What is applicable to systems, can be done to the entire process as well. Digital twins can analyse data from various sensors and control systems to identify inefficiencies in manufacturing processes. This can then be used to optimise material flow, energy consumption, and resource utilisation, leading to reduced waste and increased productivity.

4. Quality control: Another important aspect of production is quality control and in this respect, digital twins can be used to monitor product quality throughout the manufacturing process, identifying defects and deviations from specifications. This is achieved by analysing data from sensors and inspection systems, detecting potential quality issues early on, preventing them from escalating and causing further problems.

5. Training and education: Digital twins can serve as excellent training tools for operators and maintenance personnel. Since the virtual environment mirrors the real working of the system, users can interact with it through the digital twins and get acquainted with it, learn how to operate and maintain the equipment safely and efficiently. This can shorten the learning curve for new employees without the need for elaborate prototypes.

6. Remote monitoring and control: Perhaps the best application of a digital twin is for remote monitoring and control of industrial assets. This is not a case of just switching something on or off by remote, but real-time visibility and management of a plant or equipment from anywhere. This is particularly useful for geographically dispersed operations or for monitoring hazardous environments.

7. Improved collaboration: Another great application of digital twins is for collaboration between different teams, either on premises or different locations, working on a common platform by sharing data and insights, carrying out changes or modifications in design, or troubleshooting a fault.

Overall, the above applications give a very fair idea of how powerful a tool the digital twin is in optimising operations, enhancing efficiency, and driving innovation across the entire product lifecycle.

Benefits and return on investment (RoI) of digital twins

While advanced technologies like digital twins are available and they make a significant impact in discrete manufacturing as well as process industries, when it comes to implementation, the most important factor that comes into play is the return on investment (RoI). While within companies there is often a tussle between the accounts folks and technocrats, a forward looking management ought to take the decision in the best interests of the organisation, even if it entails a certain amount of risk. So is the case with digital twins. On the positive side, with the benefits becoming clear with successful use cases, adoption is now growing across industries – manufacturing, oil & gas, energy, healthcare, aerospace, smart cities, among others – and organisations are now more convinced about the value proposition.

Listed here are some of the important benefits of digital twins:

1. Operational efficiency: Digital twins, as seen in the applications section, enable real-time monitoring and predictive insights that reduce downtime. They also help optimise maintenance schedules (predictive vs. preventive vs. reactive), and reduce unplanned outages, ensuring increased equipment availability.

2. Cost reduction: Increased efficiency leads to maintenance cost savings through predictive maintenance. Optimised performance also leads to lower energy consumption and thus further cost savings. The other benefit is reduction in spare parts inventory by forecasting needs more accurately.

3. Improved product & process design: With digital twins facilitating virtual testing of products before physical prototyping, companies are now benefitted in terms of faster time-to-market. Also early identification of design flaws lowers R&D spend and prototyping costs.

4. Enhanced decision making: Digital twins are data spinners – a humongous amount of data that provides rich insights, which in turn improves asset lifecycle management. The ‘what-if’ analysis facilitated by simulation of different scenarios supports better strategic planning. An additional benefit is worker safety that results from better visibility of the plant operation.

5. Sustainability: One of the most important benefits that derives from the other benefits described above is that digital twins contribute to sustainability. Optimised energy and resource usage reduces carbon footprint, and helps industries move towards net zero goals by simulating and validating greener processes.

6. Customer experience & new revenue models: Finally, personalised products and services through simulation-driven design enables ‘as-a-service’ models by continuously monitoring asset usage, leading to better customer experience opening avenues to new revenue models.

Numerous studies and reports have demonstrated a significant RoI for digital twins across various industries. A recent report by Visual Capitalist, one of the fastest growing online publishers globally, citing a survey by Hexagon, mentions median RoIs over 200% in sectors like energy and manufacturing. Even if this sounds more of an exception, the Hexagon survey says 92% of companies tracking RoI see returns above 10%, while half of companies reported returns above 20%. It also notes that 74% of surveyed executives expect to increase their spending on digital twins next year. Companies that embrace this technology early already see the rewards, positioning themselves ahead of competitors that are slower to adapt.

Challenges and barriers to adoption

With the kind of attributes and advantages the digital twins possess as seen in the preceding paragraphs, there should be widespread adoption of this technology in industry, right? While the leading industrial players have embraced the digital twins and put them to work to great advantage, when it comes to wider adoption, there are the usual challenges and barriers, which are rather common when anything new becomes available. So what exactly are these obstacles?

Predictably, the foremost and the most significant hurdle is the cost of implementation. While the digital twin brings great value to the table, building and maintaining one requires substantial investment in sensors, connectivity, high-performance computing, besides specialised software. For many organisations, especially in capital-intensive sectors like oil & gas, manufacturing or core sector industries like mining and steel, the initial expenditure can be very high, and RoI is not visible in the short to medium term, which is a definite dampener.

Apart from cost, there is another important issue common to most industries, which is the legacy equipment and the complexities posed in integrating any new technology. In a way, this too is cost related as companies do not discard working machinery so easily, as the capital expenditure in acquiring new machinery and equipment is way too high. With legacy systems not necessarily fully compatible with the requirements of the digital twins even after retrofitting with sensors and IoT devices, management remains wary about the feasibility of whole concept, putting off decisions for another day.

Lack of adequately skilled manpower is yet another barrier as digital twins demand expertise in multiple disciplines like IoT, data analytics, artificial intelligence, and domain-specific engineering. As organisations are often struggling to find the right persons and the knowledge gap of their existing staff too wide to bridge, the entire decision making process suffers a setback.

Another challenge, no less daunting, is related to data. Digital twins require high-quality, real-time data, at a time when many companies are still facing the serious issue of data silos, incomplete records, and/or poor standardisation across systems. This is exacerbated by the cultural resistance within organisations, where employees fear digital technologies in general, viewing them as potential threats to their jobs. The fear of automation-driven job losses or increased scrutiny of their routine at work drives them even more fiercely into silos, reluctant to share not only the data but also knowledge.

Finally, there is also the ever present threat of cyber attacks and data breaches. The growing reliance on connectivity raises cybersecurity and data privacy concerns, as sensitive operational information becomes exposed to potential threats. The absence of standardisation and regulatory clarity also acts as a hindrance for widespread deployment of digital twins, but more of that in the following paragraphs.

Standards, interoperability, and best practices

When it comes to standards and frameworks for interoperability in digital twins, it is a work in progress, taking into account the various factors like security, data integrity, human-digital twin interaction, and domain-specific application, etc. Efforts are being made by various organisations like the ISO, IEC, IEEE and OPC Foundation to develop the basic standards to ensure consistent, secure, and reliable digital twin deployments.

One of the earliest is the ISO 23247 series, published in 2021, called Digital Twin Framework for Manufacturing. This defines the reference architecture, terminology, and information flow for digital twins in manufacturing. It standardises how physical entities, digital representations, and data exchange should be structured. ISO 10303 STEP – Standard for Exchange of Product Data – facilitates seamless exchange of product model data across different CAD, CAM, and PLM systems. Further, ISO 15926 is a standard for data integration, sharing, and handover in process industries, useful for lifecycle data continuity.

Then there is IEC 62832 (Digital Factory Framework), which provides a structured way to describe a digital factory model, and supports interoperability between engineering and operations. Further, the IEC 61512 (Batch Control) and IEC 62264 (Enterprise-Control System Integration) offer frameworks to link business systems with control systems, crucial for digital twin deployment.

Besides, there are industry-specific standards like OPC UA (IEC 62541), which is a widely adopted communication standard for secure, interoperable, and vendor-independent data exchange between machines, sensors, and digital twins. The MTConnect is an open, royalty-free standard that allows manufacturing equipment to share data with higher-level systems (MES, ERP, digital twins).

When it comes to architecture – how digital twins are actually built – there is a choice between Open architectures and Proprietary ecosystems. An open architecture uses standardised protocols and interoperable components for high flexibility, scalability, and integration with diverse third-party systems. This fosters a collaborative, future-proof ecosystem but potentially faces setup complexity and varied support. A proprietary ecosystem, on the other hand, is a tightly controlled environment by a single vendor, offering potentially superior quality, strong support, and seamless integration within its own products, but this comes at the cost of vendor lock-in, limited customisation, and potential future incompatibility with external technologies.

While there are merits and demerits in either, the choice between open and proprietary architectures for digital twins depends on the specific needs of the user organisation based on a few key factors like:

Virtual copies of physical assets make it possible to simulate and optimise workflows and processes. Picture credit: Bosch

Types of digital twins

There are different types of digital twins used in industry, though the basic concept is essentially the same. The difference is in the details, usually based on the scope of their application. The main types of digital twins include:

1. Component/Part Twins: These are the most basic, also the smallest, as they are used only for an individual part or component, rather than the whole machine or system. This type of digital twins relate to properties, condition, and behaviour of a single component, e.g., a cylinder or a piston, a valve, etc., and used for material stress analysis, design optimisation, or early fault detection.

2. Asset Twins: These represent an entire physical asset or piece of equipment, and actually show how various components interact within a specific machine or device, e.g., an engine or a compressor, generator or alternator. They are used for monitoring performance, predictive maintenance, operational optimisation, etc.

3. System/Unit Twins: System or Unit twins represent a group of assets that work together as a functional unit, and capture interdependencies and process flows between multiple assets within a manufacturing or process plant. Their application is for process optimisation in a production line, analysing bottlenecks, etc.

4. Process Twins: These represent end-to-end manufacturing or operational processes and are designed to simulate workflows, production steps, and process dynamics. The idea is to ensure efficiency improvement, scenario testing, throughput optimisation, and the like.

5. Plant/Facility Twins: These are for the full production facility or plant, and integrate multiple system twins to provide a holistic view of operations. They are used for tasks like plant-wide energy management, safety compliance, capacity planning, etc.

6. Network/Supply Chain Twins: As the name implies, these are applied to the entire interconnected supply chain or distribution network, to track product flows, logistics, and demand-supply dynamics. Their purpose is inventory optimisation, risk mitigation, resilience planning.

7. Human-Centric Twins: These digital twins mirror human operators, maintenance crews, or customer interactions, to simulate ergonomics, task execution, and decision-making impact. Obviously, the application of these twins are in matters concerning workforce safety, training, and performance analysis.

8. Hybrid or Composite Twins: These twins combine multiple types, i.e., two or more of the types described above, for integrated insights in specific scenarios. The purpose is to give multi-layered visibility for complex, interconnected systems. Their application is in more advanced cases like smart factory control, or industrial metaverse ecosystem.

Digital twins and industrial automation

Now having understood the basics of digital twins, the next thing to examine is, what purpose do they serve? What are the application areas? But before that, there is also the matter of how are digital twins integrated with the industrial automation ecosystem, more specifically with the PLC/SCADA/DCS environment? This is achieved by using communication protocols like OPC UA and custom APIs to establish bidirectional, real-time data exchange between the physical assets and their virtual models. This allows the digital twin to receive live data for monitoring and simulation, while also sending optimised control strategies back to the SCADA or DCS for validation and execution in the physical world, enabling predictive maintenance, performance optimisation, and virtual testing. Data flows from physical assets to the digital twin, where analytics provide insights into production processes, and these insights are then fed into the MES for real-time shop floor management and the ERP for higher-level business planning, creating a unified and intelligent manufacturing environment.

ABB PickMaster Twin, helps reduce commissioning times. Image source: ABB

When it comes to applications in industrial automation, digital twins have many, which are basically focused on optimising processes, enhancing efficiency, and improving overall performance. These objectives are achieved through key areas that include predictive maintenance, system simulation, process optimisation, and quality control. Above all, digital twins play an important role in virtual commissioning as well as operator training and simulation of actual operations. The following paragraphs take a closer look:

1. Predictive maintenance: One of the most cost-effective maintenance practices, digital twins can be used in predictive maintenance to monitor the performance of equipment and systems in real-time, allowing for the prediction of potential maintenance needs. The digital twin can identify anomalies by analysing the data from running equipment and predict when maintenance will be required, enabling proactive and timely interventions.

2. System simulation and optimisation: By simulating the behaviour of complex systems, such as production lines or entire factories, under various conditions, the digital twin allows engineers to test different scenarios, optimise production processes, and identify bottlenecks without disrupting physical operations. By simulating different layouts, workflows, and process parameters, manufacturers can fine-tune their systems for maximum efficiency and throughput.

3. Process optimisation: What is applicable to systems, can be done to the entire process as well. Digital twins can analyse data from various sensors and control systems to identify inefficiencies in manufacturing processes. This can then be used to optimise material flow, energy consumption, and resource utilisation, leading to reduced waste and increased productivity.

4. Quality control: Another important aspect of production is quality control and in this respect, digital twins can be used to monitor product quality throughout the manufacturing process, identifying defects and deviations from specifications. This is achieved by analysing data from sensors and inspection systems, detecting potential quality issues early on, preventing them from escalating and causing further problems.

5. Training and education: Digital twins can serve as excellent training tools for operators and maintenance personnel. Since the virtual environment mirrors the real working of the system, users can interact with it through the digital twins and get acquainted with it, learn how to operate and maintain the equipment safely and efficiently. This can shorten the learning curve for new employees without the need for elaborate prototypes.

6. Remote monitoring and control: Perhaps the best application of a digital twin is for remote monitoring and control of industrial assets. This is not a case of just switching something on or off by remote, but real-time visibility and management of a plant or equipment from anywhere. This is particularly useful for geographically dispersed operations or for monitoring hazardous environments.

7. Improved collaboration: Another great application of digital twins is for collaboration between different teams, either on premises or different locations, working on a common platform by sharing data and insights, carrying out changes or modifications in design, or troubleshooting a fault.

Overall, the above applications give a very fair idea of how powerful a tool the digital twin is in optimising operations, enhancing efficiency, and driving innovation across the entire product lifecycle.

Benefits and return on investment (RoI) of digital twins

While advanced technologies like digital twins are available and they make a significant impact in discrete manufacturing as well as process industries, when it comes to implementation, the most important factor that comes into play is the return on investment (RoI). While within companies there is often a tussle between the accounts folks and technocrats, a forward looking management ought to take the decision in the best interests of the organisation, even if it entails a certain amount of risk. So is the case with digital twins. On the positive side, with the benefits becoming clear with successful use cases, adoption is now growing across industries – manufacturing, oil & gas, energy, healthcare, aerospace, smart cities, among others – and organisations are now more convinced about the value proposition.

Listed here are some of the important benefits of digital twins:

1. Operational efficiency: Digital twins, as seen in the applications section, enable real-time monitoring and predictive insights that reduce downtime. They also help optimise maintenance schedules (predictive vs. preventive vs. reactive), and reduce unplanned outages, ensuring increased equipment availability.

2. Cost reduction: Increased efficiency leads to maintenance cost savings through predictive maintenance. Optimised performance also leads to lower energy consumption and thus further cost savings. The other benefit is reduction in spare parts inventory by forecasting needs more accurately.

3. Improved product & process design: With digital twins facilitating virtual testing of products before physical prototyping, companies are now benefitted in terms of faster time-to-market. Also early identification of design flaws lowers R&D spend and prototyping costs.

4. Enhanced decision making: Digital twins are data spinners – a humongous amount of data that provides rich insights, which in turn improves asset lifecycle management. The ‘what-if’ analysis facilitated by simulation of different scenarios supports better strategic planning. An additional benefit is worker safety that results from better visibility of the plant operation.

5. Sustainability: One of the most important benefits that derives from the other benefits described above is that digital twins contribute to sustainability. Optimised energy and resource usage reduces carbon footprint, and helps industries move towards net zero goals by simulating and validating greener processes.

6. Customer experience & new revenue models: Finally, personalised products and services through simulation-driven design enables ‘as-a-service’ models by continuously monitoring asset usage, leading to better customer experience opening avenues to new revenue models.

Numerous studies and reports have demonstrated a significant RoI for digital twins across various industries. A recent report by Visual Capitalist, one of the fastest growing online publishers globally, citing a survey by Hexagon, mentions median RoIs over 200% in sectors like energy and manufacturing. Even if this sounds more of an exception, the Hexagon survey says 92% of companies tracking RoI see returns above 10%, while half of companies reported returns above 20%. It also notes that 74% of surveyed executives expect to increase their spending on digital twins next year. Companies that embrace this technology early already see the rewards, positioning themselves ahead of competitors that are slower to adapt.

A digital thread provides the necessary information to create and maintain the digital twin. Image source: PTC

With the kind of attributes and advantages the digital twins possess as seen in the preceding paragraphs, there should be widespread adoption of this technology in industry, right? While the leading industrial players have embraced the digital twins and put them to work to great advantage, when it comes to wider adoption, there are the usual challenges and barriers, which are rather common when anything new becomes available. So what exactly are these obstacles?

Predictably, the foremost and the most significant hurdle is the cost of implementation. While the digital twin brings great value to the table, building and maintaining one requires substantial investment in sensors, connectivity, high-performance computing, besides specialised software. For many organisations, especially in capital-intensive sectors like oil & gas, manufacturing or core sector industries like mining and steel, the initial expenditure can be very high, and RoI is not visible in the short to medium term, which is a definite dampener.

Apart from cost, there is another important issue common to most industries, which is the legacy equipment and the complexities posed in integrating any new technology. In a way, this too is cost related as companies do not discard working machinery so easily, as the capital expenditure in acquiring new machinery and equipment is way too high. With legacy systems not necessarily fully compatible with the requirements of the digital twins even after retrofitting with sensors and IoT devices, management remains wary about the feasibility of whole concept, putting off decisions for another day.

Lack of adequately skilled manpower is yet another barrier as digital twins demand expertise in multiple disciplines like IoT, data analytics, artificial intelligence, and domain-specific engineering. As organisations are often struggling to find the right persons and the knowledge gap of their existing staff too wide to bridge, the entire decision making process suffers a setback.

Another challenge, no less daunting, is related to data. Digital twins require high-quality, real-time data, at a time when many companies are still facing the serious issue of data silos, incomplete records, and/or poor standardisation across systems. This is exacerbated by the cultural resistance within organisations, where employees fear digital technologies in general, viewing them as potential threats to their jobs. The fear of automation-driven job losses or increased scrutiny of their routine at work drives them even more fiercely into silos, reluctant to share not only the data but also knowledge.

Finally, there is also the ever present threat of cyber attacks and data breaches. The growing reliance on connectivity raises cybersecurity and data privacy concerns, as sensitive operational information becomes exposed to potential threats. The absence of standardisation and regulatory clarity also acts as a hindrance for widespread deployment of digital twins, but more of that in the following paragraphs.

Digital twins are rapidly transforming the manufacturing industry. Image source: Freepik

When it comes to standards and frameworks for interoperability in digital twins, it is a work in progress, taking into account the various factors like security, data integrity, human-digital twin interaction, and domain-specific application, etc. Efforts are being made by various organisations like the ISO, IEC, IEEE and OPC Foundation to develop the basic standards to ensure consistent, secure, and reliable digital twin deployments.

One of the earliest is the ISO 23247 series, published in 2021, called Digital Twin Framework for Manufacturing. This defines the reference architecture, terminology, and information flow for digital twins in manufacturing. It standardises how physical entities, digital representations, and data exchange should be structured. ISO 10303 STEP – Standard for Exchange of Product Data – facilitates seamless exchange of product model data across different CAD, CAM, and PLM systems. Further, ISO 15926 is a standard for data integration, sharing, and handover in process industries, useful for lifecycle data continuity.

Then there is IEC 62832 (Digital Factory Framework), which provides a structured way to describe a digital factory model, and supports interoperability between engineering and operations. Further, the IEC 61512 (Batch Control) and IEC 62264 (Enterprise-Control System Integration) offer frameworks to link business systems with control systems, crucial for digital twin deployment.

Besides, there are industry-specific standards like OPC UA (IEC 62541), which is a widely adopted communication standard for secure, interoperable, and vendor-independent data exchange between machines, sensors, and digital twins. The MTConnect is an open, royalty-free standard that allows manufacturing equipment to share data with higher-level systems (MES, ERP, digital twins).

When it comes to architecture – how digital twins are actually built – there is a choice between Open architectures and Proprietary ecosystems. An open architecture uses standardised protocols and interoperable components for high flexibility, scalability, and integration with diverse third-party systems. This fosters a collaborative, future-proof ecosystem but potentially faces setup complexity and varied support. A proprietary ecosystem, on the other hand, is a tightly controlled environment by a single vendor, offering potentially superior quality, strong support, and seamless integration within its own products, but this comes at the cost of vendor lock-in, limited customisation, and potential future incompatibility with external technologies.

While there are merits and demerits in either, the choice between open and proprietary architectures for digital twins depends on the specific needs of the user organisation based on a few key factors like:

- What is the need for integration? If it is to connect with a vast array of existing or future systems, then open architecture is a better choice.

- For better control and stability, especially for users who prefer a curated, high-quality experience with strong support and not much concern for external integration, a proprietary ecosystem may be suitable.

- In terms of future strategy, Open architectures are generally considered more agile and future-proof, making them a strategic advantage for a dynamic digital transformation journey.

The implementation of digital twins is an important decision for an organisation and needs careful consideration of all aspects. However, very briefly here are the best practices for implementing digital twins in manufacturing:

- Make a small beginning with a pilot project before plant-wide deployment.

- Define what the digital twin should achieve (e.g., predictive maintenance, process optimisation).

- Ensure high-quality, standardised, and real-time data integration from sensors, machines, and IT/OT systems.

- Use open standards (e.g., ISO 23247, OPC UA) for interoperability to avoid vendor lock-in and enable smooth integration.

- Secure data flows, especially when connecting OT with IT and cloud environments, with effective cybersecurity measures.

- Involve operations, IT, engineering, and business units for holistic adoption.

- Cover the entire product/plant lifecycle (design, build, operate, maintain).

- Use machine learning for predictive insights, not just visualisation.

- Keep the digital twin synchronised with physical changes to ensure accuracy.

- Track performance improvements, cost savings, and downtime reductions to justify scaling.

Conclusion

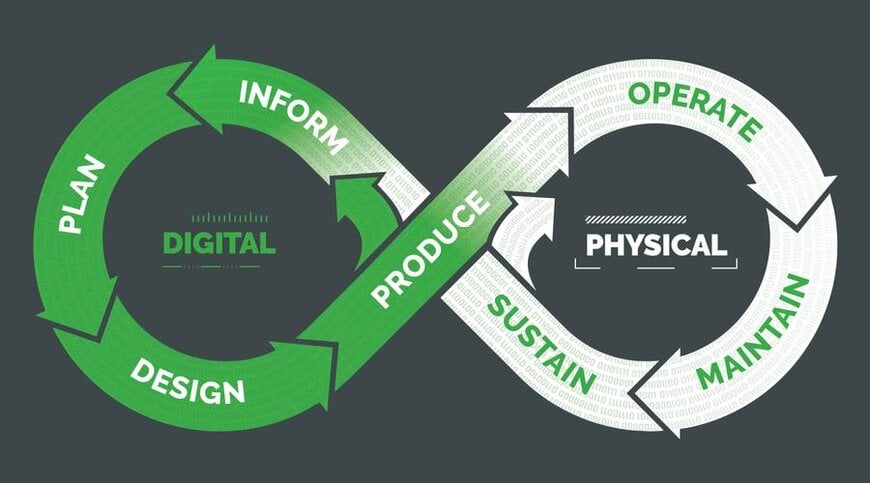

The manufacturing industry is rapidly transforming, bridging the gap between the physical and digital worlds. Digital twins are an important part of this transformation. By enabling manufacturers to simulate, monitor, and optimise operations in real time, digital twins help unlock unprecedented levels of efficiency, quality, and innovation. With data integration and AI-driven analytics, digital twins provide actionable insights to reduce downtime, extend asset life, and accelerate product development cycles. More importantly, they support predictive and prescriptive decision-making, in the process help transit from reactive to proactive maintenance and further, even autonomous operations.

Yet these are early days; not the entire industry is on the same page of this chapter of advanced automation. Successful adoption requires a holistic approach – aligning technology infrastructure, workforce skills, cybersecurity, and governance frameworks with clear business objectives. As industry standards evolve and interoperability improves, digital twins will become more accessible and scalable across enterprises of all sizes. For manufacturers, embracing digital twins is no longer optional but essential. Ultimately, they serve as a cornerstone of Industry 4.0, empowering companies to be resilient, a prerequisite for future-ready ecosystems that can contribute meaningfully to long-term growth and sustainability.

The manufacturing industry is rapidly transforming, bridging the gap between the physical and digital worlds. Digital twins are an important part of this transformation. By enabling manufacturers to simulate, monitor, and optimise operations in real time, digital twins help unlock unprecedented levels of efficiency, quality, and innovation. With data integration and AI-driven analytics, digital twins provide actionable insights to reduce downtime, extend asset life, and accelerate product development cycles. More importantly, they support predictive and prescriptive decision-making, in the process help transit from reactive to proactive maintenance and further, even autonomous operations.

Yet these are early days; not the entire industry is on the same page of this chapter of advanced automation. Successful adoption requires a holistic approach – aligning technology infrastructure, workforce skills, cybersecurity, and governance frameworks with clear business objectives. As industry standards evolve and interoperability improves, digital twins will become more accessible and scalable across enterprises of all sizes. For manufacturers, embracing digital twins is no longer optional but essential. Ultimately, they serve as a cornerstone of Industry 4.0, empowering companies to be resilient, a prerequisite for future-ready ecosystems that can contribute meaningfully to long-term growth and sustainability.