Adoption of state-of-the-art processing machines boosts productivity ~Driving more autonomous operations

I-PEX Inc., an electronic component and automotive parts manufacturer headquartered in Fushimi-ku, Kyoto, Japan, operates approximately 20 Mitsubishi Electric processing machines at its die manufacturing site.

www.mitsubishielectric.com

I-PEX Inc.

Key Points

- Automated operations running overnight reduce the workload and overtime demands on operators.

- Using NC control reduced machining errors and increased the operating rate by approximately 20%.

- Work that would typically take three days is now completed in two.

By replacing manual grinding activities with a numerical controlled (NC) wire electro-discharge grinding (WEDG) process, the company has enhanced its operations, improving product quality and throughput while reducing the number of repetitive tasks for operators.

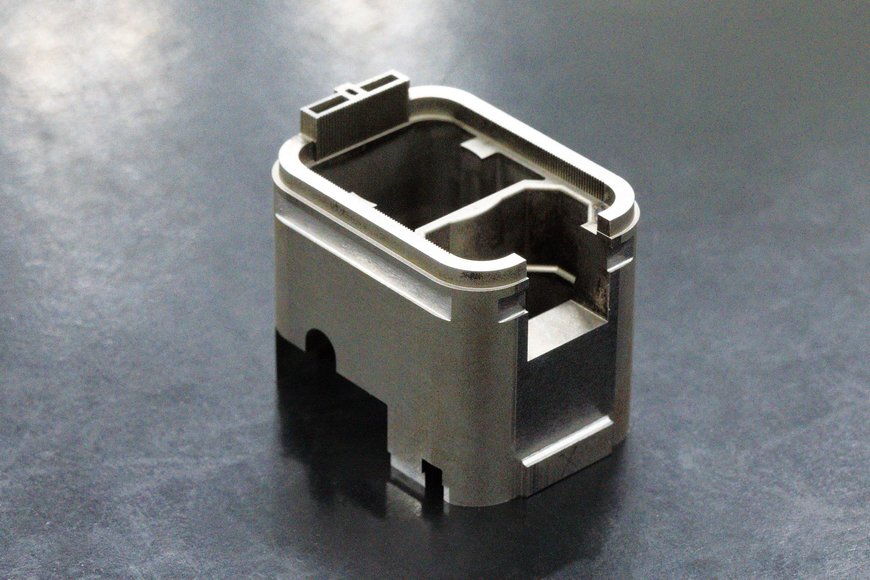

Sample of an injection mold die part. Wire machining and electrical discharge machining have been used for its production.

Utilizing anti-electrolysis machines

I-PEX is committed to improving die manufacturing productivity. In line with this pledge, they installed Mitsubishi Electric's MP2400 ultra-high-precision wire EDM machine as a replacement for manual grinding activities. The numerical controlled (NC) wire electro-discharge grinding process helped reduce the number of repetitive tasks for operators.

The MP2400 wire EDM machine was installed in 2018. I-PEX is progressively moving away from manual grinding operations in favor of NC machining. Hajime Kuga says he wants the work surface and operation panel to be adjustable to meet the needs of its diverse workforce.

Kuga explained the reason for this selection, “We heard from Mitsubishi Electric that the MP2400 can reduce the phenomenon of the softening of the machining surface after wire electrolysis to almost zero. After a sample processing test we were also able to get the results we wanted, so we decided to go with this machine.”

The softening of the eroded surface layer of the work piece, a form of electrolytic corrosion, occurs due to the interaction of the processing fluid, deionized water, and the direct current used for cutting. However, in the case of the MP2400, electrolysis-free machining is achieved by a high-speed anti-electrolysis power supply (AE power supply).

“Depending on the shape of the piece being worked, it may take more time than machining with a grinder, but the MP2400 can operate unattended overnight, reducing the workload on the operator and potential requirement for overtime,” Kuga tells us. The MP2400 has improved the performance of automatic threading of the cutting wire, and this has decreased errors during machining, improving the NC operating ratio by about 20%.

Hajime Kuga, Deputy General Manager of the Production Equipment Department, Electronic Components Division.

Improved productivity for larger die manufacturing

In 2020, the company installed a new SV12PM machine, Mitsubishi Electric’s ultra-high-precision die-sinking EDM. The goal was to increase productivity in the manufacture of large dies for automotive parts. “We installed this system based on our in-house findings, indicating that the larger the machining area, the greater the reduction in machining time. While this does depend on the size of the die and what is being machined, in our plant, work that took three days to complete with conventional equipment can now be accomplished in two days, and this is a great benefit,” says Kuga. He also explained that the PC-based screen operation improved usability.

The SV12PM (upper photo) die sinking EDM was installed in response to requests from the Automotive Division, which produces relatively large die. Processes that could take three days with the existing EV12VM machine can now be completed in two days, improving productivity.

The MP2400 and SV12PM both utilize Mitsubishi Electric's iQ Care Remote4U for remote monitoring of operating status and errors. The I-PEX team intends to increase automation in the die manufacturing processes through the utilization of new equipment and services. Kuga said, “With the cooperation of Mitsubishi Electric and other processing machine manufacturers, we plan to increase the ratio of automated NC processes to improve work efficiency allowing us to focus our staff on highly skilled tasks that will have to remain manual, such as post-processing measurement and correction, cleaning, final polishing, and assembly.”

Leveraging technical roundtables

The close relationship with Mitsubishi Electric is supporting I-PEX’s overall growth strategy. Akihiko Hara, Director, Managing Executive Officer and General Manager of the Electronic Components Business Division, said, “We plan to leverage key opportunities, such as technology roundtable meetings with Mitsubishi Electric, to improve our core technical capabilities and, at the same time, promote transformation in both our operations and business model.”

Akihiko Hara, Director, Managing Executive Officer, General Manager of Electronic Components Division

Hara said, “While continuing to grow our existing core business of manufacturing electronic and automotive components, we want to expand into new areas, such as the production of piezoelectric MEMS devices that utilize single-crystal films, photoelectric connectors that are crucial for future data centers and telecommunication base stations, as well as healthcare and DNA analysis equipment.” This strategy will put the company on the path to boost sales from 66.8 billion JPY ($47 million) in FY2021 to 100 billion JPY ($703 million) in FY2030.